Introduction

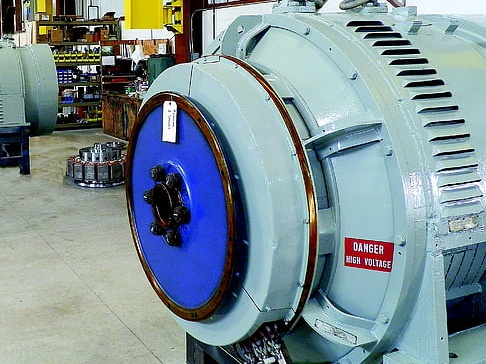

Permanent magnet direct drive motors have been of prime importance due to the changing face they bring with them to industries, propelled by high efficiency, high power density, and direct drive. These motors represent a paradigm change in engineering and design and offer substantial advantages compared to traditional motor systems.

One of the major advantages is their very high efficiency, reducing energy consumption and operating costs. High power density complements this efficiency, enabling these motors to provide more power from a given size than would be possible with conventional motors.

Besides, the direct drive nature of these motors precludes the use of traditional speed reducers and transmission mechanisms. This simplifies not only the overall system architecture but also enhances reliability by reducing the number of moving parts and points of potential failure.

Above all, permanent magnet direct drive motors are disruptive innovations, not incremental improvements; hence, they raise the bar on performance, efficiency, and reliability in industries like renewable energy generation, industrial automation, and electric vehicles. Their adoption marks progress toward more sustainable and efficient technological solutions.

Analysis of torque characteristics of permanent magnet direct drive motor

Some of the major factors that influence torque characteristics of Permanent Magnet Direct Drive motors involve their performances and operational effectiveness in an enormous range of applications.

Motor Design and Magnetic Field Distribution

In particular, PMDD motor design makes a lot of difference in torque characteristics. Typically, most PMDD motors are of multi-pole structure, which provides a nearly uniform magnetic field distribution. However, in practice, ion-uniform distribution may result in variation in torque production, consequently affecting the performance and efficiency of motors. Therefore, to smooth the operation of motors, some measures have to be taken, such as optimization of magnetic pole designs with improved uniformity of the magnetic field.

Current Control Methods

For torque characteristic definitions, effective current control is vital. These control strategies, such as PWM and vector control, which will be discussed next, can effectively regulate the magnitude and waveform of the current supplied to the motor with great influence.

PWM Control: Alters the average value of the current by pulse width modulation; hence, it is a method that could effectively control torque output. The method is simple; hence, it is applicable in situations where precise torque control is not of essence.

Vector Control: It exercises more sophisticated control, independently controlling the flux and torque components of the current. The result is that it offers a precise readjustment, well adapted to changes in load, both for torque accuracy and dynamic responsiveness.

Influence of Load Characteristics

Characteristics of the load driven by PMDD motors directly influence torque output. The variables of different loads that bear an effect on torque transmission and its management by the motor include rotational inertia and damping characteristics.

Rotational Inertia: A load with high inertia needs higher torque to achieve a certain speed or acceleration. It thus affects the choice and tuning of control strategies toward optimum performance of the motor.

Damping Characteristic: Highly damped types of loads absorb and dissipate energy, and this directly affects a motor’s ability to provide steady torque output and responsiveness.

Integration of Control Strategy with Load Characteristics

Selection of the control strategy in PMDD motors should be performed on given the particular characteristics of the load to be driven. In this way, by matching the control strategy to the load requirements, optimal torque delivery, efficiency, and longevity of the motor system can be achieved. A properly integrated system will therefore maximize torque accuracy, reduce energy losses, and maintain operating stability throughout a wide operating envelope.

The torque characteristics analyzed for Permanent Magnet Direct Drive motors underline the great importance of thoughtful motor design, precision in current control methods, and consideration of load dynamics. All these taken into proper consideration ensure that optimal performance and efficiency with enhanced reliability will be obtained in various industrial applications of motors. Continuous technological development will allow further refinement in torque characteristics by new design and control strategies, which surely will drive these PMDD motors even further as a prime mover in modern industrial automation, transportation, and renewable energy systems.

Control strategy of permanent magnet direct-drive motor

The following are the common strategies for the permanent magnet direct drive motor torque characteristics:

Vector control strategy: Vector control is one of the decoupling controls that can independently control the flux and torque components of the motor. Real-time adjustment of the current amplitude and phase can be done to achieve accurate torque and speed control. Its advantages are a fast response speed and high control accuracy. It is suitable for applications with high torque dynamic performance requirements.

Direct torque control strategy: The control approach is adopted as the direct torque control strategy, whereby the torque of the motor is detected and controlled directly Based on this, fast response and precision control of the motor can be realized. Meanwhile, no complex coordinate transformation exists and the structure is simple and intuitive. However, direct torque control requires high precision from a torque detection device and its performance may be easily influenced due to the variation of parameters for the motor.

To avoid the overheating and destruction of the motor in high-speed operation, a weak magnetic control strategy should be adopted to reduce the magnetic field strength of the motor. The weak magnetic control strategy:c can be implemented by adjusting the current and voltage of the motor. By adopting the weak magnetic control strategy, the maximum speed of the motor will increase with the unchanged power of the motor. However, weakened magnetic control reduces the torque output capacity of the motor; therefore, it is very important to ensure rotational speed while reasonably controlling torque output.

Intelligent control strategy: permanent magnet direct drive motor control finds its wide application with the intelligent control strategy based on the developments made in the field of artificial intelligence technology. The motor torque and speed can be forecasted by using neural networks, fuzzy control, and some other intelligent algorithms. Its excellent advantages include strong adaptability and good robustness of the intelligent control strategy. An adaptive adjustment is given according to the operating state and load demand of the motor in real operation. Thus, improvement in the operating efficiency and stability of the motor is effective.

Optimization of control strategy

Based on this, further performance enhancement to be pursued in permanent magnet direct drive motors should target optimization and improvement of their control strategy. A few usual methods for the optimization are:

Identification and optimization of parameters: Accurately identifying the motor parameters will optimize the control strategy parameter settings in favor of improving the control precision and stability. For instance, the recognition of the motor resistance, inductance, and other parameters online allows for real-time adjustment of the vector control strategy parameter value to adapt to changes in the operating state of the motor.

Torque observation and compensation: The torque fluctuation can be minimized and the accuracy of control can be improved by the method of torque observation and compensation. Through real-time monitoring of the torque output of the motor and compensating for the observed torque fluctuations, the torque error can be reduced and the smooth running performance of the motor can be improved.

Predictive control: the future change of torque and speed can be forecasted based on the history and operating status of the motor by the method of predictive control, and effective measures can be taken accordingly. In other words, the running state of the motor can be intervened early and adjusted in advance to improve the response speed and stability of the whole system.

Conclusion

As a kind of high-efficiency and energy-saving drive method, the permanent magnet direct-drive motor has a wide range of application prospects in modern industry, transportation, energy, and other fields. Its advantages can be fully utilized and the performance of the system can be improved by understanding its torque characteristics and selecting an appropriate control strategy. In practical applications, it is necessary to optimize and improve the system according to the specific load characteristics and operating requirements, to adapt to the ever-changing working environment and usage requirements.