PREVIEW

Both high-voltage motors and low-voltage motors of air compressors have their respective merits and demerits. What are their respective advantages and disadvantages?

Compared with low-voltage motors, high-voltage motors have the following advantages:

Compared with low-voltage motors, high-voltage motors have the following disadvantages:

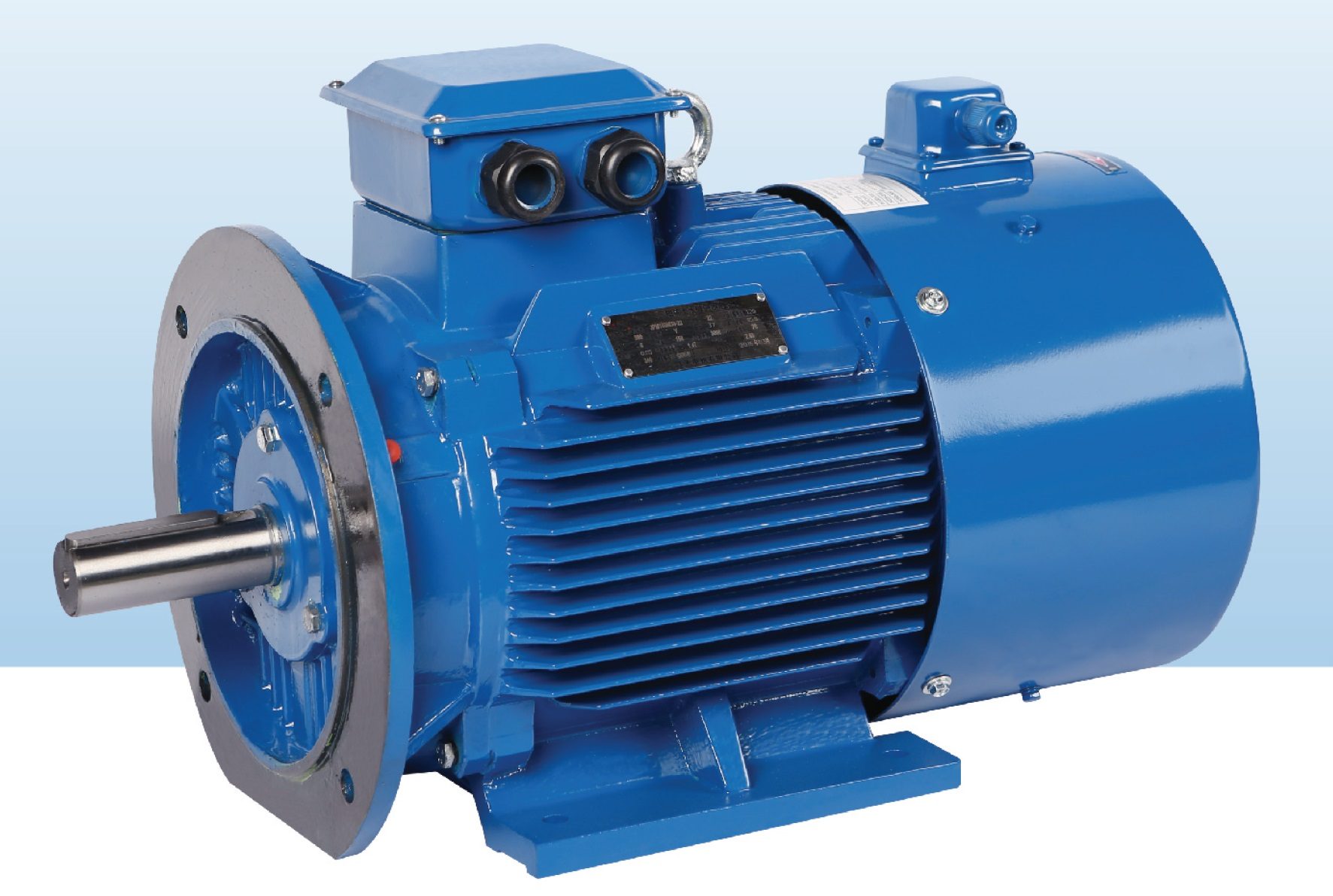

ENNENG permanent magnet motors and energy-saving solutions for air compressors

ENNENG is the leading innovator in the motor industry, striving to offer high-efficiency, energy-saving motor solutions, especially for air compressors. We have strived to house a few important changes to create the best-responding series against this widely alarming concern about power overconsumption by air compressors: Energy-Efficient permanent magnet Motors with Variable Frequency Drive (VFD) Models. These innovative motors can substantially reduce power consumption for the user, hence assuring an economically viable and environment-friendly operation system.

Characteristics of ENNENG Permanent Magnet Motor

High Efficiency and Energy Saving: The permanent magnetic material used in ENNENG permanent magnet motors is a rare earth. With high magnetic strength, there is low load torque while starting up and running the motor. Thus, it requires less current. In comparison with asynchronous motors of the same specification, the efficiency of the motor increases by 10%-15%, with an evident power-saving effect.

Control the temperature rise: Strictly controlling the rise in temperature in the motor ensures that, during operation, the temperature of the motor is less than 60K, prolonging the service life of the compressor and reducing maintenance costs.

Soft start, stable running: Equipped with a permanent magnet rotor and permanent magnet motor, it can make the permanent magnet motor achieve a soft start. It avoids impacts on compressors when super powerful mechanical motors start at full pressure and ensures the running smoothly of compressors.

Energy-saving Programme of Air Compressor

Variable-speed operating condition optimization: The ENERGY permanent magnet motor allows the variable speed driving of the air compressor’s motor to run at high efficiency for a wider speed range. This saves energy whatever the operating condition of the compressor.

Constant output pressure: Compressors with the ENNENG permanent magnet motor will be able to change the optimal speed toward real-time air demand and make the output pressure invariable. It saves not only a little energy but also increases work efficiency.

Flexible Motor Power Configuration: It is intended that the permanent magnet motor system allows users to order rated motors based on actual operating requirements. Via closed-loop control, the speed of the motor will automatically change with the pressure conditions. Consequently, energy would not be wasted even during light operation conditions.

Professional customization and technical support

The technical team in our company is professional, with several permanent magnet motors that can offer customized solutions in different compressor applications with consideration of the functional needs and required efficiency. Engineers will surely provide good service for you and suitable advice according to your situation.

In a nutshell, the permanent magnet motor and energy-saving solution for air compressors of ENNENG Group will have the users more economically operating the air compressors. By choosing our products from ENNENG, that means you’re already sowing for tomorrow’s world with less use of energy, ecological suitability, and high efficiency. Please contact us!