In the background of rapid development and growing pressure on resources and the environment of the global economy, the plastics processing industry is facing the double challenges of transformation upgrading and green development. Plastic extruders are the key equipment in the plastics processing industry; the technological innovation and application to promote the industry’s efficient and green development are of great significance.

Performance of plastic extruder

Plastic extruders are the most important equipment in plastics processing. Their technological development and status quo directly influence the industry’s production efficiency and product quality. In modern times, with the advancement of science and technology, plastic extruders have been continuously improved in structure, control system, and energy saving and consumption reduction.

Structural design: The module structure adopted by modern extruders makes the whole equipment structure more compact and easier to maintain. Meanwhile, optimize the design of screws and barrels, and other key components to improve the equipment’s extrusion efficiency and product quality. Besides, some advanced extruders are equipped with an automatic screen changer that effectively reduces the downtime in the production process and improves production efficiency.

Control system: the intelligent and automatization trend of plastic extruders becomes more obvious. In the modern plastic extruder, there is an advanced electric control system and sensor. The temperature can be precisely controlled, pressure regulated, and speed governed. These intelligent control systems improve not only the stability during the production process but also reduce the difficulty of operations and make production easy and convenient.

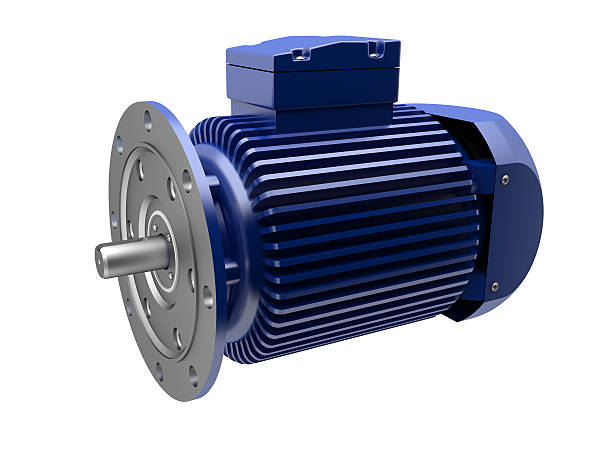

Energy saving and consumption reduction: Plastic extruders, by using permanent magnet motors such as TYB Series Standard Type Permanent Magnet Motor, can achieve the goal of green manufacturing. With advantages in efficiency, low emissions, and resource conservation, the contribution of permanent magnet motors to energy saving and environmental protection is remarkable, and they are becoming an important choice for energy-saving retrofits. Permanent magnet motor applications assist plastic extruders in reducing costs and increasing efficiency.

Application Advantages of Plastic Extruders in the Plastics Processing Industry

Significant effect of improving production efficiency

This means that an extruder features continuous production attributes that are seamless, hence greatly raising the output efficiency. Compared to other conventional molding methods, the process of extrusion molding enjoys a higher degree of automation with greatly reduced human interference, which means that, in essence, the entire production process is considerably faster. The advantages of the extruder also lie in its strong extrusion ability, hence assuring fast product output and enabling it to meet the increasingly higher market demand for plastic products.

Precise control of product quality

Plastic extruders ensure that the dimensional accuracy, surface quality, and physical properties of plastic products meet the standard requirements through precise control of key parameters such as temperature, pressure, and speed. In this way, not only is the qualified rate of the product improved but also, the product will be more competitive in the market. In the extruding technique, the mixing uniformity of raw materials is assured effectively, which further develops the overall quality of products.

Adaptability of a wide range of applications

Extruder plastic has an extensive range of adaptability, able to process multiple types of plastic raw material, including polyethylene, polypropylene, and polyvinyl chloride among others. This product series can satisfy diversified demands from the market through replacement with different molds and different extrusion heads to extrude plastic products in a wide range of shapes and specifications. For this flexibility, the plastic extruder plays an important role in the plastics processing industry today, and as a motivating power, the promotion function exerts the development of the plastics processing industry as well.

Simple structure with the assistance of a permanent magnet motor

Now, with the development of science and technology, on account of their excellent properties, high efficiency, and small size, permanent magnet motors have been applied to more and more fields and also can be seen in plastic extruders. The transmission devices such as gearbox, coupling, pulley, and others are superfluous for this type of motor, and this greatly simplifies the structure of the plastic extruder and saves its maintenance. Besides, permanent magnet motors can also increase the performance and efficiency of the equipment by a great degree. In addition, the equipment’s performance and efficiency can also be greatly enhanced.

The Positive Role of Plastic Extrudersgreenn Productionn

Green production has become a development trend in the plastic processing industry with the enhancement of the environmental awareness of human beings. Plastic extruders can play a positive role in green production.

First, through optimizing the production process and equipment configuration, it can decrease energy consumption in the production process. For example, in an extruder, permanent magnet motors reduce energy consumption and emission at a high level. In addition, the optimization of the extrusion process can minimize the production of waste and defective products, hence reducing the pollution of the environment.

Besides, plastic extruders promote the growth of a circular economy in the plastics processing industry. It is during the production process that the extruder manages to regenerate wastes from plastic products and reshape them for use in going back into production after having gone through some processes of crushing, cleaning, and drying. Such recycling work not only avoids the waste of resources but also can bring a reduction of production costs, resulting in a better economic and environmental benefit simultaneously.

Reducing Energy Consumption and Waste Emissions

Optimization of production processes and configuration of equipment can help plastic extruders reduce energy consumption and waste emissions. Permanent magnet motors have proved to drastically reduce energy use and, consequently, lower emissions. Besides, optimization of the extrusion process reduces waste and defective product production, which minimizes environmental pollution.

Promoting Circular Economy

Plastic extruders also contribute to the development of a circular economy in the plastics processing industry. They enable the recycling and reutilization of waste plastic products by processing them through crushing, cleaning, and drying. This recycling reduces resource waste and production costs, achieving economic and environmental benefits.

Plastic extruders are key components in the machinery assembly of the plastics processing industry, greatly improving operational efficiency and sustainability. Their development through technological innovation and wider application enhances production without compromising product quality, as it creates an eco-friendly industrial environment that is beneficial for the circular economy. With the further development of science and technology and a variation in market demands, the contribution of extruders to transformative growth in the industry cannot be gainsaid. They are sure to play a very important part in the sustainability of continued, effective enhancement of the industry in years to come.

Continuous development and application of plastic extruders are quite essential for efficient and green development within the plastics processing industry. Emphasis should be directed toward improvement in structural design, control systems, and energy efficiency. It will be possible to overcome the dual challenges of increased production with being environmentally friendly by integrating permanent magnet motors. Moving into the future, plastic extruders will be leading this development step by step for the efficient and green development of plastics processing worldwide.