Wastewater treatment is among the most critical processes in terms of environmental sustainability and public health protection. With a growing population worldwide, the shift to urban areas also puts much pressure on wastewater management. One of the important factors that may help in the optimization of wastewater treatment procedures is the use of technologically advanced devices, such as permanent magnet motors.

Permanent magnet motors have become one of the disruptive technologies in many sectors, such as wastewater treatment. Permanent magnet motors draw their drive based on the magnetic properties of rare earth permanent magnets. Permanent magnet motors can also provide higher efficiency, reliability, and precision than conventional motors.

This paper will attempt to explain permanent magnet motors as they are applied to renovated sewage treatment facilities. Their benefits and any possible limitations have to be understood in one’s thorough understanding of just what the role of enhancement to wastewater treatment is going to be. Real-case case studies can be investigated further for an explanation of the positive impact that wastewater treatment plants worldwide are realizing from permanent magnet motors.

The successful application underlines the great opportunity of permanent magnet motors to optimize the process of purification at wastewater treatment plants. The paper calls for further research and development in this area in our striving for more effective and greener modes of management regarding wastewater.

In the following sections, an overview of permanent magnet motors applied in wastewater treatment will be provided, the advantages of permanent magnet motors over conventional motors will be discussed, some real case studies will be presented, and a summary of the prospects of these motors in revolutionizing wastewater treatment facilities will be made.

Overview of the application of permanent magnet motors in wastewater treatment

Permanent magnet motors have been widely used in wastewater treatment processes for their excellence in efficiency, reliability, and accuracy. In this section, some applications of permanent magnet motors for wastewater treatment with various advantages and disadvantages will be presented.

Wastewater pumping station

Permanent magnet motors also find wide application in wastewater pumping stations because they drive the pumps transferring waste water between different stages of its treatment process. Such motors demonstrate higher efficiency, longer lifetime, and lower maintenance than conventional motors. Besides that, in many cases, the pumping station is a key point of the wastewater treatment process, and permanent magnet motors provide reliable continuous operation in such cases.

Aeration system

Aeration is one of the most important processes in wastewater treatment, enhancing the growth and activity of microorganisms that degrade waste. Permanent magnet motors find application in aeration systems to drive blowers, which supply air to wastewater. Permanent magnet motors boast higher efficiency, lower noise, and lower vibration than traditional motors, thus making them ideal for application in sensitive environments such as wastewater treatment plants.

Sludge mixer

Sludge mixers homogenize the sludge, a product derived from wastewater treatment processes. Permanent magnet motors for this application have increased for reasons such as their ability for high torque output with superior speed control while at low noise levels. It improves mixing efficiency in a sludge mixer and brings in energy consumption minimization together with reduced maintenance cost.

Filtration and centrifugation equipment

Permanent magnet motors are used in filtration and centrifugal machinery in the process of removing impurities and contaminants in wastewater. These motors show higher efficiency, low noise output, and less maintenance and hence are ideal for such applications.

Advantages of permanent magnet motors

Although permanent magnet motors enjoy some advantageous features over conventional motors when applied in wastewater treatment processes, they have equally good numbers of limitations. Most importantly, permanent magnet motors are higher in cost compared to conventional motors.

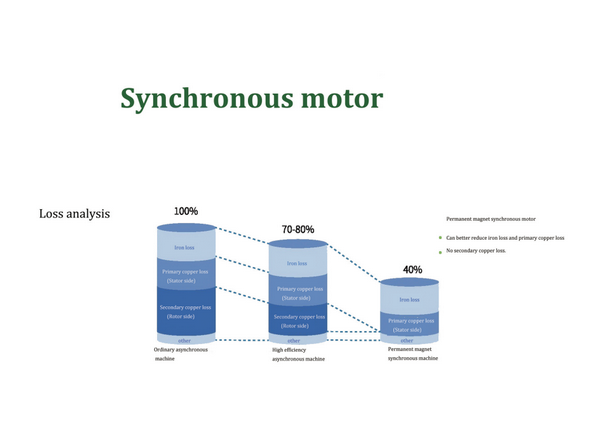

Higher efficiency

Permanent magnet motors are more efficient compared to conventional motors. They can run at higher power density, while the losses are much lower. Much better energy savings can be realized, together with a reduced operating cost in this way. The consumption of energy in the context of a wastewater treatment plant is one of the major operating costs. The permanent magnet motors could thereby have great contributions to make by helping cut down on the amount of energy consumed to make improvements in their entirety.

Longer service life

one of the other prominent advantages of permanent magnet motors over conventional motors is the increased service life. Moreover, permanent magnet motors without brushes and commutators cause less wear and therefore provide longer working hours with less frequency in maintenance. This ensures that the running costs remain low, coupled with a high-reliability ideal for a wastewater treatment plant.

Improved accuracy

Permanent magnet motors are more precise and in control compared to traditional ones. It provides precise speed control, high torque, and low vibration that make it very ideal for those applications requiring accurate and steady operation. Permanent magnet motors have several important advantages in sensitive processes at wastewater treatment plants, such as aeration and mixing, which require consistent and uniform performance.

Noise reduction

Since there are no brushes and commutators, permanent magnet motors are much quieter than traditional motors. This makes them ideal for applications that require low noise levels, such as wastewater treatment facilities located near residential areas. Noise reduction also contributes to a safer and more comfortable working environment for personnel operating the wastewater treatment plants.

Environmentally friendly

Last but not least, permanent magnet motors are very eco-friendly, having lower energy consumption and carbon emissions compared to conventional motors. This will make them very suitable for all the wastewater treatment plants looking to reduce their carbon footprint and meet their sustainability goals.

Improved reliability

Permanent magnet motors are more reliable and require less maintenance compared to traditional ones. They are designed to be simple, with few moving parts, and no brushes, or commutators. This factor reduces failure possibilities and low maintenance needs, which consequently decreases the time of wastewater treatment plants’ downtime. This contributes to a decrease in maintenance costs.

Higher power density

Permanent magnet motors have higher power density compared to conventional motors. They provide more power in smaller packages, making them ideal for space-constrained applications. In wastewater treatment plants, equipment is often installed in small spaces. Using permanent magnet motors helps optimize space utilization and increase efficiency.

Permanent magnet motors will have several key advantages for sewage treatment plants. These include high efficiency, long service life, high precision and control, low noise, environmental sustainability, high reliability, and high power density. Such merits make permanent magnet motors an attractive option for the optimization of wastewater treatment plants by improving environmental sustainability, performance, and reliability, given the ever-increasing pressures related to cost reduction.

Realistic case study 1: A city sewage treatment plant

In the renovation of the aeration system in one city sewage treatment plant, the driving device for the aeration fan was a permanent magnet synchronous motor. Traditional aeration systems are induction motors or other kinds of drives. However, the treatment plant chose permanent magnet synchronous motors to realize higher efficiency and lower energy consumption.

Excellent performance was attained after the commissioning of this PMSM-driven aeration blower. Comparatively, energy consumption has been highly reduced compared with traditional driving methods. Through monitoring and data analysis, the treatment plant finds that not only does a permanent magnet synchronous motor run well under a rated load, but it also keeps high efficiency even during partial load and low load conditions, which will extremely improve the energy efficiency of the whole aeration system.

Besides, the noise of permanent magnet synchronous motors is much lower. In this way, the surroundings and the health of employees will be much improved. After the use of permanent magnet synchronous motors, the maintenance cost and lost time of the treatment plant are considerably reduced, further improving the reliability and stability of the sewage treatment plant by a big margin.

This case illustrates that permanent magnet motors could be used as the driving device for major wastewater treatment equipment to effectively advance energy efficiency, reduce the operating cost, enhance the adaptability of the environment, and also increase the reliability and stability of the device.

Real-life Case Study 2: Industrial Water Pump System

Large volumes of seawater need to be pumped out by an industrial facility in a coastal city for cooling purposes. Conventional pumping systems of induction motors with centrifugal pumps have large energy consumption and require a lot of maintenance.

Given this perception, the plant preferred replacing the motors with a permanent magnet synchronous motor, PMSM, and axial flow pumps for the centrifugal pumps. The axial pump driven by a new PMSM is designed for operation in the VFD system. When cooling water demands vary, the system automatically operates the pumping system speed control.

In this paper, after the new pumping system had been installed and commissioned, the facility greatly reduced its energy consumption and operating costs. Compared with induction motors, PMSMs have higher efficiency and power density; hence, they consume less energy and reduce carbon emissions addition, the VFD system makes the pump work within an optimal speed range, thus further improving general energy efficiency.

Besides, PMSM-driven axial flow pumps have a longer life and higher reliability that cuts down maintenance and saves on downtime. According to the estimates of the plant, the new system will pay for itself in two years due to energy savings and reduced maintenance costs.

This case study shows that replacing conventional motors and pumps with permanent magnet motors and axial flow pumps in industrial water-pumping systems can realize significant energy efficiency gains, operating cost savings, and equipment reliability and service life increases.

Real case studies on wastewater treatment to industrial water-pumping systems illuminate the benefits of permanent magnet motors. The permanent magnet synchronous motors considerably enhance energy efficiency, reduce operational costs, increase reliability, and enhance environmental adaptability. These case studies have demonstrated the potential of permanent magnet motors in driving sustainable and efficient solutions for a wide array of industries. Permanent magnet motors will continue to bring a greener and more reliable future in many fields.