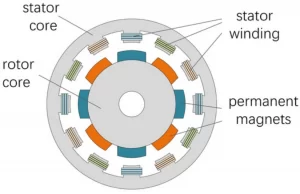

Permanent Magnet Synchronous Motors (PMSMs) are broadly utilized in industrial settings because of their superior efficiency and dependability. Yet, like all electrical devices, they may encounter breakdowns over time. Grasping typical failure trends aids in avoiding extended interruptions and pricey fixes.

When a Permanent Magnet Synchronous Motor begins to falter, various clues might emerge. A prominent hint is odd shaking, which could point to rotor troubles, misalignment, or bearing deterioration. Excessive heat is another frequent issue. This often stems from heavy strain, inadequate airflow, or insulation breakdown. Uneven speed changes or abrupt halts might suggest electrical glitches, such as uneven voltage or winding flaws. Also, a drop in force output may hint at issues with the motor’s magnets or control setup.

Spotting motor problems early can ward off expensive failures. A motor running poorly uses extra power, which hikes electricity costs. Plus, it risks harming linked parts, raising overall upkeep bills. For instance, in a factory environment, an ignored stator fault might cause the motor’s magnets to lose strength. This cuts efficiency and may demand a full motor swap. Routine checks and swift action ensure small hitches don’t grow into major setbacks.

Proper troubleshooting of a PMSM requires an organized method to uncover the failure’s source.

Before diving into troubleshooting, safety comes first. Make sure the motor is unplugged from its power source. Also, wear protective gear like insulated gloves and safety glasses. Having the right equipment is vital for precise findings. A heat-sensing camera can spot overheating. Meanwhile, a multimeter checks voltage and resistance. And a vibration tool can detect mechanical unevenness.

The initial move in troubleshooting is examining the electrical setup. Uneven voltage across phases can make the motor run poorly or overheat. Use a multimeter to gauge voltage on each phase. Ensure it stays within the advised range. Another key task is testing the windings’ insulation strength. Faulty or worn insulation might trigger short circuits, heightening failure odds. Doing an insulation resistance check reveals if rewinding or insulation fixes are needed.

Mechanical parts like bearings, the rotor, and the shaft need scrutiny too. Worn bearings can cause excess friction. This leads to overheating and lower efficiency. A misaligned rotor might spark vibrations and uneven force output. If the motor shaft is warped or bent, replacing it may be necessary. Poor lubrication is another common snag. Too little grease ramps up friction, while too much can cause leaks and dirt buildup.

The surroundings where a motor runs greatly affect its lifespan. Dampness can rust inner parts. Meanwhile, dust piles can block air vents, causing overheating. In places with harsh temperatures, heat expansion and shrinkage might stress mechanical bits. If a PMSM works in tough conditions, adding protective shields or using coated parts can boost toughness.

For motors facing ongoing troubles despite basic checks, advanced methods offer deeper understanding.

Vibration analysis is a powerful way to find flaws not seen in simple reviews. By studying the vibration frequency range, you can spot rotor imbalance, misalignment, or bearing issues. Each mechanical problem creates a unique vibration signature. This lets repair crews zero in on the trouble’s root.

Heat imaging can uncover warm spots in the motor, showing areas of excess heat. High heat in stator windings might mean insulation failure. If bearings show elevated temperatures, it could signal grease issues or too much friction. Regular heat scans help catch problems before they turn into big failures.

Testing under real loads can reveal performance flaws not obvious when idle. Run the motor at varying load levels. Then, technicians can watch for speed shifts, force changes, or efficiency dips. This approach helps spot power supply hiccups, overheating under strain, or weak magnets.

Preventive care is crucial for keeping PMSMs reliable and efficient over time.

A set maintenance plan helps dodge sudden breakdowns. Monthly checks should cover listening for strange sounds, tracking vibration levels, and ensuring proper greasing. Every three months, tasks might include testing insulation strength, clearing air paths, and checking for loose wires.

Enhancing certain parts can stretch a motor’s life. Heat-proof magnets can stop strength loss in extreme settings. Also, rust-resistant coatings guard against moisture harm. Using top-notch lubricants and bearings built for fast spins can lift motor output too.

Keeping a PMSM within its designed boundaries prevents strain-related flops. Motors pushed past their limits might overheat, wear faster, and lose efficiency. Correctly sizing the motor for its job is key to avoiding undue pressure on parts.

Some motor woes need expert help, especially when issues linger despite efforts.

If a motor keeps failing after several fix attempts, pro diagnostics might be required. Constant overheating, efficiency drops, or odd speed swings could point to tricky electrical or mechanical faults needing specialized skills. Magnet strength loss or control system flops are best left to seasoned pros.

ENNENG excels in crafting and building Permanent Magnet Synchronous Motors for diverse industrial uses. With over ten years of know-how, ENNENG delivers custom motor options that boost efficiency, trustworthiness, and sturdiness. Their cutting-edge design and precise crafting ensure motors hit global benchmarks, suiting fields like mining, water processing, and production.

Overheating might come from too much load, weak airflow, or winding insulation trouble. Steady upkeep and good cooling setups help avoid these woes.

Demagnetization is typically permanent. Still, it’s avoidable with proper heat control and shielding from extreme temperatures.

Bearing life varies with usage conditions. Regular vibration checks spot early wear signs, enabling timely swaps before breakdowns.

Efficiency slips might stem from part wear, magnet weakening, or lax upkeep. Routine reviews and part upgrades can keep performance strong.

Grasping common Permanent Magnet Synchronous Motor failure trends and using a clear troubleshooting path can stop pricey breakdowns. Regular care and advanced diagnostic tools ensure lasting efficiency and dependability.

Facing repeated motor troubles? ENNENG’s engineering squad offers tailored fixes suited to your exact needs. Reach out today to explore high-output Permanent Magnet Synchronous Motors built for efficiency and toughness. Let’s fine-tune your operations for top-notch results!