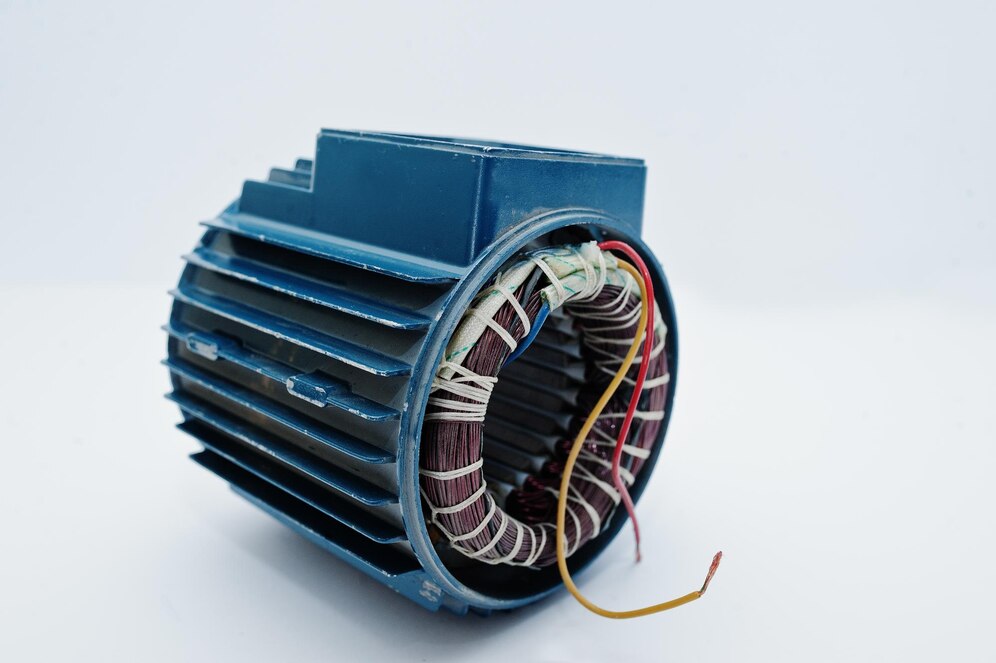

Permanent magnet direct drive motors find their usage widely with the development and process of industrial automation and green energy. Since permanent magnet direct drive motors are of high efficiency, low maintenance, and compact structural design, they become very important in many fields. As the power and speed are continuously increasing, the EMI problem generated by permanent magnetic drive motors becomes of high importance. Therefore, the detailed analysis of electromagnetic compatibility for permanent magnet direct drive motors has become a prime factor in ensuring that the motors operate stably and exert less interference on other equipment.

Analysis of electromagnetic interference sources

The electromagnetic interference mainly occurs because of changes in current and magnetic field inside a permanent magnet direct drive motor. During its operation, the fast variations of the stator current will generate a transient magnetic field. Rotation of the rotor permanent magnets will also produce a variable magnetic field. The transient magnetic fields and the changes in current will create an electromagnetic field around the motor and thus produce electromagnetic radiation and conduction interference.

Changes in stator current: During its operation, the motor undergoes very fast changes in stator current. These create a transient magnetic field, generating electromagnetic radiation. This might interfere with other electronic equipment present around it.

Rotor Permanent Magnet Rotation:Finally, rotation of the rotor permanent magnet results in a change of the magnetic field and, consequently, a time-varying magnetic field around the motor. This may interfere with the normal operation of surrounding electronic equipment.

Phase change process: in the motor results in rapid changes in the current and hence a very large electromagnetic interference. Such interference can propagate through a power line or space radiation and can affect the surroundings.

Electromagnetic compatibility influencing factors

Motor design parameters: include winding structure and number of windings and wire diameter, which would directly affect electromagnetic interference generation. Reasonable designs-such as multi-layer winding-can contribute to increase the space between windings so that the electromagnetic interference can be reduced.

Working environment: the working condition of the motor, such as speed, load, and temperature, will also affect electromagnetic compatibility. Under high-speed and high-load working conditions, the electromagnetic interference that may be generated by the motor is serious. In addition, the intensity of an electromagnetic field, the temperature, and humidity in the working environment will also impact electromagnetic compatibility.

Power quality: Power quality is one of the major factors that determine the EMC performance of permanent magnet direct drive motors. A fluctuation in power supply easily results in an unstable condition of motor current and a magnetic field, further increasing electromagnetic interference.

External equipment: the laying and electromagnetic sensitivity of the surrounded electronic equipment can also have an impact on the permanent magnet direct drive motors in EMC performance. Such as, the other equipment’s electromagnetic radiation may generate an interfering impact on a permanent magnet direct drive motor in normal working status while the electromagnetic radiation of the permanent magnet direct drive motor may have its impact on other equipment, too.

EMC optimization measures

The following optimization measures can be taken to improve the electromagnetic compatibility of permanent magnet direct drive motors:

Motor design optimization: improvement of winding structure, increase of shielding layer, and optimization of air gap size, which reduce electromagnetic interference generation. Meanwhile, using high-performance insulating materials and optimizing the heat dissipation design improves the stability of the motor operating under high-temperature and high-humidity conditions.

Filtering and suppression: Add filters to the motor power line and signal line for filtering out the conducted interference signal. In addition, the intensity of electromagnetic radiation can be suppressed by using magnetic beads, capacitors, and other components to reduce its effect on equipment around.

Electromagnetic shielding:Lay conductive material on the motor shell and key parts, form an electromagnetic shielding layer to reduce the leakage of electromagnetic radiation. Meanwhile, reasonably arrange electronic equipment around the motor in order to avoid mutual interference.

Improve the working environment: Increase the electromagnetic compatibility of the motor by reducing the strength of the electromagnetic field within the working area. Additionally, the working conditions need to be neat and dry in order to prevent dust and moisture from affecting the operational functionality of the motor.

Power quality improvement:Using a stable power supply can reduce the impact of power fluctuations on the EMC of the motor. Consider using UPS or filters to improve the quality of power.

EMC testing: Improve the testing of EMC during the design and production of motors. Testing can reveal potential electromagnetic interference problems, and measures for improvement should be taken accordingly.

Conclusion

In a word, it is of great importance that electromagnetic compatibility should be performed during their application and development. Therefore, some effective steps to improve the EMC performance of permanent magnet direct drive motors are as follows: optimization in design and construction of the motor, application of filtering and suppression techniques, electromagnetic shielding technique improvement, improvement of operating environment of the motor, and upgrading power quality.