High-speed motors have the benefits of high efficiency, large specific power, high power factor, high reliability, and are easy to maintain. Developed in the advanced industrial nations, high-speed motors have widely been used in various fields such as aviation aerospace, and mold industries in these countries. The High-Speed Motor Industry entered China during the 1990s. Products have continued their development from low-end to high-end, and accordingly, the market size expanded further.

Definition of High-speed Motors

High-speed motors differ from conventional motors due to the magnitude of their rotational speeds and the high levels of engineering involved in their design. As their name suggests, these motors are capable of attaining very high levels of rotational speed, ideal for applications where this would prove advantageous. Although what constitutes a high-speed motor may be subject to variation, several criteria serve as a guideline in their classification.

Criteria for High-speed Motors

Rotational Speed:

It mainly uses the rotational speed to classify the high speed of a motor. In most classifications, the generally accepted revolving speed to classify the high-speed motors is more than 10,000 r/min. That threshold value is so much higher when compared with that of regular industrial motors, which are usually below 3,600 r/min. It has to be perfectly and thoroughly designed and processed to maintain such high-order speeds under stability, durability, and performance.

Linear Speed of Rotor Rotation:

Apart from the rotational speed, other important characteristics of high-speed motors are given by the linear speed of rotor rotation. The linear speed in this context means the speed at which any point on the rotor travels in space. For high-speed motors, this is more than 50 meters per second. This again is an important parameter because it influences the performance of the motor and the stresses within the rotor.

Relation between Centrifugal Stress and Linear Speed:

Centrifugal stress, or the relation thereof to linear speed, forms a basic theory in designing high-speed motors. Centrifugal force or, rather, the resultant produced acts in an outward direction from the spinning rotor, and their magnitudes vary with the square of linear speed. By that, it means if a doubled value of linear speed increases centrifugal stress, the resulting increase is exponential; doubling of linear speed, for instance, gives fourfold centrifugal stresses. This relationship highlights the engineering challenges involved in designing high-speed motors, as materials and structural integrity must withstand these elevated stresses without compromising performance or safety.

In practice, such stresses in high-speed motors are normally mastered by making use of advanced materials and construction techniques. For instance, rotors can be manufactured from high-strength alloys or composite materials capable of sustaining such high forces at very high speeds. Besides, precision balancing and alignment become crucial to keep vibrations as low as possible and diminish the possibility of mechanical failure.

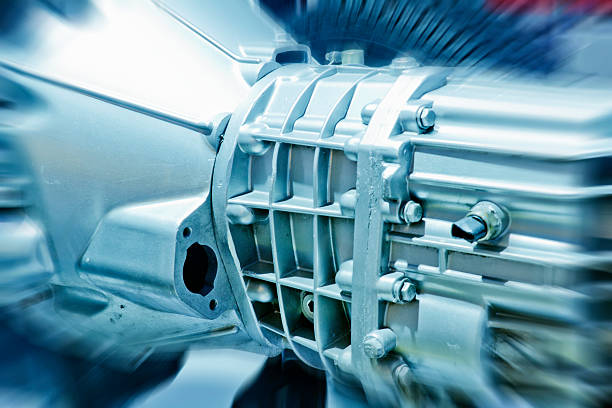

Design and Material Considerations:

Construction materials in the rotor and stator of a high-speed motor must be capable of bearing high centrifugal force and be resistant to its forces of deformation. Standard material choices include high-strength steel, titanium alloy, and carbon fiber composites. These provide good strength with minimal weight, something very important to help maintain the high rotational speed.

High-speed motor design also considers mechanisms of advanced cooling to dissipate the heat generated by friction and electrical losses at high speeds. Cooling methods may include forced air cooling, liquid cooling, or even the use of special cooling jackets around critical components.

Applications and Implications:

High-speed motors find their applications in many areas where their peculiarities are of great benefit. The applications in aerospace go toward implementing high power density and reliability in systems. Within the medical field, these high-speed motors serve to drive precise surgical tools and imaging devices. Other applications include industrial high-speed machining and precision manufacturing where their efficiency and accuracy augment productivity.

High-speed motors are defined by such criteria as extremely high rotational and linear speeds, high centrifugal stresses resulting from them, and the advanced engineering involved in keeping those factors in check. High-speed motors go beyond 10,000 r/min and linear speed higher than 50 m/s, push the envelope in advanced applications, and underline the need for innovative design and material science in their development.

Applications of high-speed motors

Applications of high-speed motors are increasing explosively. In order of high speed, there are the following applications.

The electric tool uses a coreless PCB winding process and integrates with the control chip. It is very compact. That kind of electric converter also can be used in some medical equipment such as dentistry.

High vacuum normally can be obtained by the molecular pump, which is one kind of physical device. It also can be utilized for air separation and clean air with high quality. The motor speed for such applications may achieve 32 k r/min, 500 W. It can be designed by an induction motor or by a concentrated winding permanent magnet motor. It can be designed using an induction motor or a concentrated winding permanent magnet motor.

There are many subdivisions in energy storage, such as aircraft-used flywheel energy storage, power-station-used flywheel energy storage, and so on. The following example is one flywheel energy storage product for a vehicle driving. The concept it holds is the same as the hybrid vehicle battery energy storage or supercapacitor energy storage. In such a situation, when the automobile needs a surge in power, the flywheel energy storage motor can behave just like a generator to supply electricity. The following is an energy storage motor with 30 kW of power and 50 kr/min of rotation speed. It uses an induction motor scheme and its rotor is a solid iron block.

Electronic turbocharging is a new technology developed in recent years. Its function is to supercharge the automobile engine at low speeds to delay the vortex lag and increase the explosive torque. A 10 kW, 100 kr/min product developed by BorgWarner uses a 2-pole, 24-slot permanent magnet motor structure. Due to the high working environment temperature, in addition to the high speed, the design of this kind of motor should also take control of the magnetic field. Loss of steel and increased temperature.

This must be one of those ‘legendary’ products from a university lab – a machine the size of a pencil can erupt into 50 kW. Sure enough, it could take an automobile engine by this, as it reportedly states, “shrinking by 95% and a great many devices rely on this tiny engine – so that “

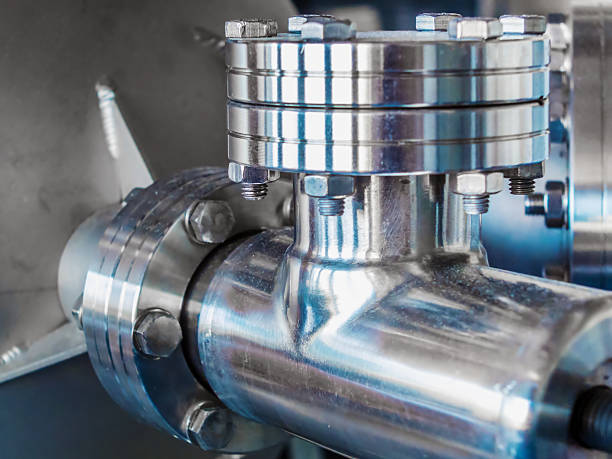

Up to today, the high-speed air compressor can be seen as one of the most common applications of the high-power high-speed motor. Its rotation speed may reach tens of thousands of rpm with power between 100-700 kW, and it generally uses magnetic bearings, driving turbines, or blades through the motor to compress the air. The high-speed direct drive motor cancels the original low-speed motor + speed increaser system, which has a compact structure and high reliability. Two kinds of commonly used ones are surface-mounted permanent magnet synchronous motors and induction motors.

The vehicle drive motor is the hottest field at present, and the mainstream speed of passenger cars is within 16,000 r/min and higher speed motors are already being developed.

To improve power density further, the Integral Powertrain designed and developed a permanent magnet motor system operating at 20,000 r/min and 450 kW with a maximum torque of 900 N·m with a mass of only 28 kg. It uses advanced technologies including winding oil injection cooling, radial stator, rotor axial cooling, and so on.

With the acceleration of electrification and semi-electricity in aircraft, high-power, high-speed motors have become increasingly in demand. Higher-power aviation motors are used in hybrid aircraft. As such, it forms the core of similar extended-range hybrid architectures. These generally use forced air-cooling structures to take advantage of high airflow at high speeds. Permanent magnet motors are more used than induction motors to raise efficiency.

ENNENG specializes in the research and development of all kinds of high-speed motors. These motors will be efficient and reliable with high speed.

ENNENG‘s high-speed motors are widely used in industries such as power stations, metallurgy, chemicals, water treatment, coal mining, textiles, rubber, petroleum, medicine, paper, cooling towers, and food processing. These motors help companies reduce emissions, save energy, reduce consumption, and minimize noise, promoting green production practices.

High-speed motors are famous for their efficiency and energy-saving performance from the manufacturer ENNENG. These motors have power factors of over 98%, which means efficiencies of more than 95%, making the capacity of power-receiving equipment small and saving lots of energy. They should be easily replaceable for those with the same installation size as asynchronous motors.

Also, PG vector control ensures the high accuracy of the speeds needed by some specific applications thanks to the high-speed motors ENNENG produces. All compactors and printers need that motor.

Generally, ENNENG high-speed motors are designed to ensure excellent performance and reliability at higher speeds. With the added advantages of energy savings, easy replacement, and variable speed control, the series of motors is an ideal choice for industrial customers who value optimal performance and low energy consumption.