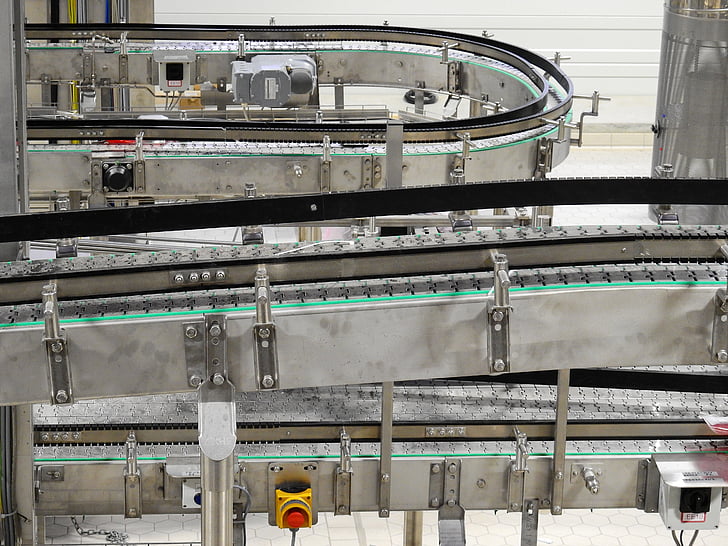

Belt conveyors are among the most distributed devices in logistic handling and transportation processes within contemporary industry. They find broad usage either for goods, raw material, or product handling, sorting, and storage; however, taking into account the inefficiency and very high energy consumption of electric motors widely used as a rule in conventional belt conveyors, there definitely exists a need to provide more sustainable and ecologically friendly power solutions.

As a new power solution, permanent magnet synchronous motors boast excellent efficiency, high torque density, and fast responsiveness. Plenty of advantages make it perform well in belt conveyor applications.

Status and Challenges of Belt Conveyors

Belt conveyor is one of the common materials handling equipment that transports materials from one place to another using a conveyor belt running between two drums. However, conventional belt conveyors have a number of limitations. First, most of them are driven by conventional induction motors, which are not very efficient at partial loads and find difficulty in responding quickly to real-time changes in demand. Secondly, conventional belt conveyors are not very efficient with regard to energy utilization, and there is a large amount of energy that goes to waste. Besides, traditional conveyor systems have high maintenance costs and are not very sustainable.

Recently, belt conveyor development in industries has increased to improve issues of efficiency in conveying, energy consumption, and the sustainability of the system. For operation, general conventional belt conveyors consume huge amounts of energy. However, they happen to be quite energy-intensive, especially whenever the case is that the load becomes partial or processes which also involve stop-and-start motions. This has resulted in energy losses with increased production costs. The pressures for environmental and sustainability performance from the public are driving industrial companies today to pursue more friendly and more energy-efficient solutions for the conveyor system.

Overview of Permanent Magnet Synchronous Motors

A permanent magnet synchronous motor is a form of the motor if the fundamental operation principles for permanent magnets are considered onto the rotating magnetic field that was developed by the AC power source.

When three-phase AC power feeds a stator coil, it establishes a working principle based on the use of a rotating magnetic field. A torque developed between the permanent magnetic field developed by the permanent magnets and this rotating magnetic field acts to drive the motor to rotate. Compared with traditional induction motors, permanent magnet synchronous motors have higher efficiency and a higher power factor at rated load due to permanent magnet material usage. Their advantages over traditional induction motors are mainly in the following respects. First, permanent magnet synchronous motors have higher energy efficiency, which could help raise the overall efficiency of the system by reducing the energy loss while converting electrical energy. Second, permanent magnet synchronous motors have a higher power factor, which could help reduce the reactive power loss in the system and raise the power utilization of the transmission system. Besides, the permanent magnet synchronous motor has a high response speed, extremely short start-up time, fast output torque adjustment, thus helping to improve dynamic and control performance of the belt conveyor system. Permanent magnet synchronous motors have been applied in several fields: hydroelectric power and wind power generation have significant successful instances.

The permanent magnet synchronous motors will become a new kind of motor technology in current industrial attention with high efficiency, high power density, and no excitation loss. High expectation for applications in the field of belt conveyors would promise to bring new possibility for performance improvement of conveyor system on account of its advantages.

Permanent Magnet Synchronous Motor in Belt Conveyor Application

Principle of operation of permanent magnet synchronous motors is quite different from the standard induction motors to drive the belt conveyors.

While in conventional motors, torque is generated by the principle of electromagnetic induction, in permanent magnet synchronous motors, torque generation is by the interaction of the magnetic field created by permanent magnets and the alternating current in the stator windings. This makes the PMSM even more efficient and accurate in starting, accelerating, and stop operation. Permanent magnet synchronous motors can greatly improve the efficiency of belt conveyors, reduce energy consumption in application, and provide many other advantages that can be used to the full through their high efficiency, high torque density, and quick response: much more output power with low power loss can be gotten by them. Permanent magnet synchronous motors are estimated to be 10-20% more efficient than conventional induction motors, reducing energy consumption and operating cost. Besides, due to the high responsiveness and precision control characteristics of permanent magnet synchronous motors, belt conveyors can be more flexible and effective in such processes as starting, stopping, and speed regulation.

Precautions and Future Prospects

Precautions for Permanent Magnet Synchronous Motors in Belt Conveyors

Although permanent magnet synchronous motors have many advantages in belt conveyors, there are a few important points in operational processes that deserve our attention.

Cost: Permanent magnet materials are relatively highly expensive; hence, permanent magnet synchronous motors can be fairly costly to build. However, with technological advancement and as the economy of scale improves, the cost of permanent magnet material is coming down gradually. Furthermore, due to increased competition, the cost of permanent magnet synchronous motors will also decrease.

Magnetic field stability: Permanent magnet synchronous motors need high stability in magnetic fields.

Necessary measures therefore need to be taken to ensure the magnetic field is stable. Permanent magnet material and magnetic field stability could hence be affected under poor operation conditions such as particles, dust, or humidity in operating environments usually experienced by belt conveyors. This paper, therefore, considers what protection and maintenance measures may be taken so that such negative circumstances do not jeopardize stability and reliability for permanent magnet synchronous motors.

High Temperature Issues: In most applications, belt conveyors work at high temperatures that may affect the performance and life of permanent magnet materials. These include the short-term high temperature characteristics and long-term high temperature stability of permanent magnet materials. In solving this problem, cooling systems can be used or permanent magnet materials with higher temperature tolerance can be selected.

Future Trends for Permanent Magnet Synchronous Motors in Belt Conveyors

Technology improvement: With further research and development of permanent magnet material and motor control technology, the efficiency of PMSM will continue improving. The newly developed and applied permanent magnet material will bring higher magnetic field stability and temperature tolerance, further enhancing the reliability and adaptability of permanent magnet synchronous motors driving belt conveyors.

Intelligent and adaptive control: The future of automation technology for the development tendency of the belt conveyor is intelligent and adaptive. It also achieves a high level of automation and intelligent control in productivity increase and energy efficiency with the characteristic of precise control, which is the advantage of the permanent magnet synchronous motor serving as the drive.

Sustainability: Permanent magnet synchronous motors are high-efficiency motor technology that could provide huge energy savings and environmental protection. As the world is becoming more aware of environmental sustainability, permanent magnet synchronous motors are expected to find wide application in the field of belt conveyor systems for the achievement of sustainable production methods.

In a word, the permanent magnet synchronous motors will have great prospects in the development of belt conveyors. Through further technological innovation and exploration of applications, permanent magnet synchronous motors will surely yield a much more effective, reliable, and sustainable belt conveyor system in the future. That is to say, it will provide industrial production with an effective and environment-friendly solution.