Traditional metal drawing equipment has a lot of problems, such as high energy consumption, complex structure, and high maintenance costs. By adopting a low-speed and high-torque permanent magnet direct-drive motor, we can solve these problems effectively. The promotion and application of this advanced motor technology will give the wire drawing machine industry more efficient, energy-saving, and environmentally friendly solutions.

Advantages of permanent magnet direct drive motors

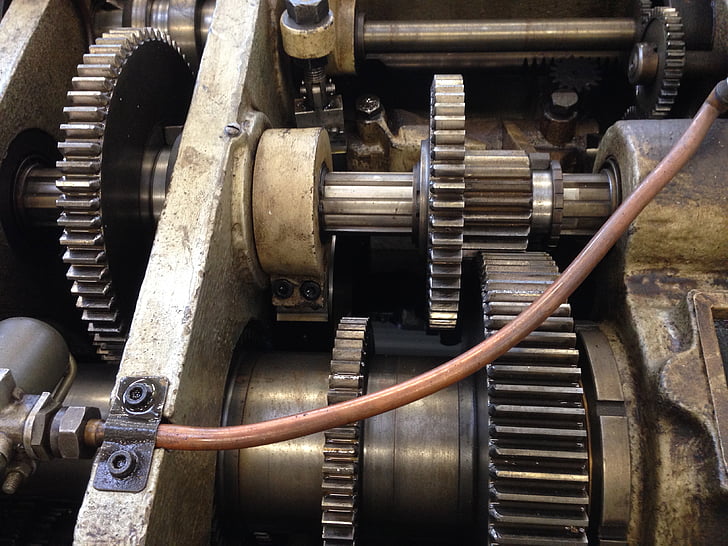

A permanent magnet direct drive motor uses a permanent magnet as the excitation source and directly drives the load with power. Compared to traditional frequency conversion speed control motors, the following characteristics are:

Low energy consumption: Permanent magnetic direct drive motor has a simple structure. The loss of mechanical transmission is reduced; it promotes the transmission efficiency. This reduces energy consumption in systems with much higher efficiency than that of traditional motors.

High torque density: In permanent magnet materials for permanent magnet direct drive motors, the magnetic field strength, and magnetic energy density are high. A larger output torque can be provided with greater volume.

Fast Response: Permanent magnet direct drive motors, due to their structural characteristics of the direct drive of the load, guarantee fast response. This allows precise control and regulation, suitable for applications requiring high speed and positioning. Application advantages brought in by permanent magnet direct drive motors in the field of metal drawing machines include:

High performance: Most of the traditional metal drawing machines take hydraulic or mechanical ways of driving, which is done with a high energy loss. The permanent magnet direct drive motor acts in a direct driving fashion, hence reducing the power conversion link and increasing transmission efficiency; thus, consuming less energy.

Energy saving and environmental protection: permanent magnet direct-drive motors are characterized by high efficiency and low energy consumption, which can reduce the waste of energy and is good for environmental protection. In comparison with the traditional variable-frequency speed control motor, the former can better meet the requirements of energy saving and emission reduction.

Low noise: traditional metal drawing equipment often produces noise pollution, which affects the working environment and workers’ health. The permanent magnet direct drive motor can provide a quieter working environment due to its direct drive method, which reduces the friction and vibration of the transmission parts.

Maintenance-free: Permanent magnet direct drive motors are characterized by a simple structure, and there is no other maintenance work to be performed. It doesn’t require periodic lubricant replacement compared to the traditional motor or repair of the mechanical transmission parts, thus reducing the maintenance cost and extending the service life of the equipment.

The metal drawing machine industry can, therefore, realize more efficient, energy-saving, and environmentally friendly ways of production by adopting energy-efficient permanent magnet direct drive motors. This advanced motor technology improves the transmission efficiency and service life of the equipment, and reduces energy consumption and maintenance costs, thus bringing huge economic and environmental benefits to the organization.

Permanent magnet direct drive motors in wire drawing machines

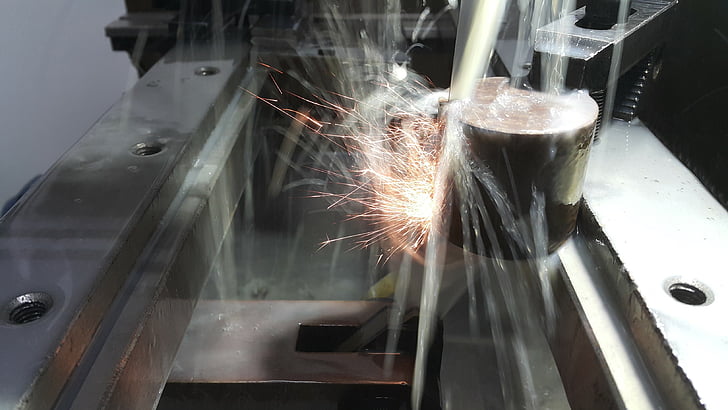

A permanent magnet direct drive motor is increasingly widely used in the field of metal wire drawing machines for its low speed with high torque, which makes it a very important part of a wire drawing machine. In the drawing process, the metal wire requires the application of a large amount of torque to stretch the metal material. However, such applications are often unable to meet these requirements due to the existing speed-torque characteristics, thus limiting the traditional frequency-conversion speed control motor. Permanent magnet direct drive motors have excellent low speed high torque performance and could offer stable and reliable output to ensure the quality and efficiency of metal drawing.

Permanent magnet direct drive motors have the advantage of improving the intrinsic loss problems of traditional wire drawing machines. The traditional wire-drawing machinery, with hydraulic or mechanical transmission, possesses low transmission efficiency due to energy conversion links, hence huge energy loss. Contrarily, a permanent magnet direct-drive motor can adopt a drive mode with low transmission links and loss of energy conversion to promote high transmission efficiency and low consumption.

Furthermore, due to the compact structure of the permanent magnet direct drive motor, no additional transmission device is required, and therefore more flexible laying can be made in the wire drawing machine and save valuable installation space. Meanwhile, permanent magnet direct-drive motors can provide more stable and reliable power output in the process of metal drawing, improving the efficiency of motors and overall productivity.

Comparison of permanent magnet direct-drive motor performance with asynchronous frequency-regulated motors

In the field of drawing machines, the use of conventional asynchronous frequency-regulated motors generally needs to be equipped with a transmission device to achieve low speed and high torque output. The additional transmission device will inevitably lead to energy conversion loss. For the permanent magnet direct drive motors, through direct drive, the energy conversion link is reduced and the energy loss is reduced correspondingly.

The power, power factor, and energy-saving target of permanent magnet direct drive motors vary with different loads. According to the experiment data, at 60% load, the power consumption, power factor, and energy saving target of permanent magnet direct drive motor are respectively 15%, 30%, and 40% lower than that of the traditional asynchronous frequency-regulated motor. That means in real work, permanent magnet direct drive motors can make better use of energy rather than waste it.

Conclusion

As a kind of energy-saving driving technology, the permanent magnet direct drive motor possesses an essential position and a vast application perspective in the industrial field. Shortly, efficient drives will gradually displace conventional driving techniques. Permanent magnet direct-drive technology can play a huge role not only in high-power equipment like metal drawing machines but also in the application of machinery manufacturing. The permanent magnet direct-drive motor will be further developed to improve its performance to be widely used in each industry and contribute more to the promotion of sustainable development.