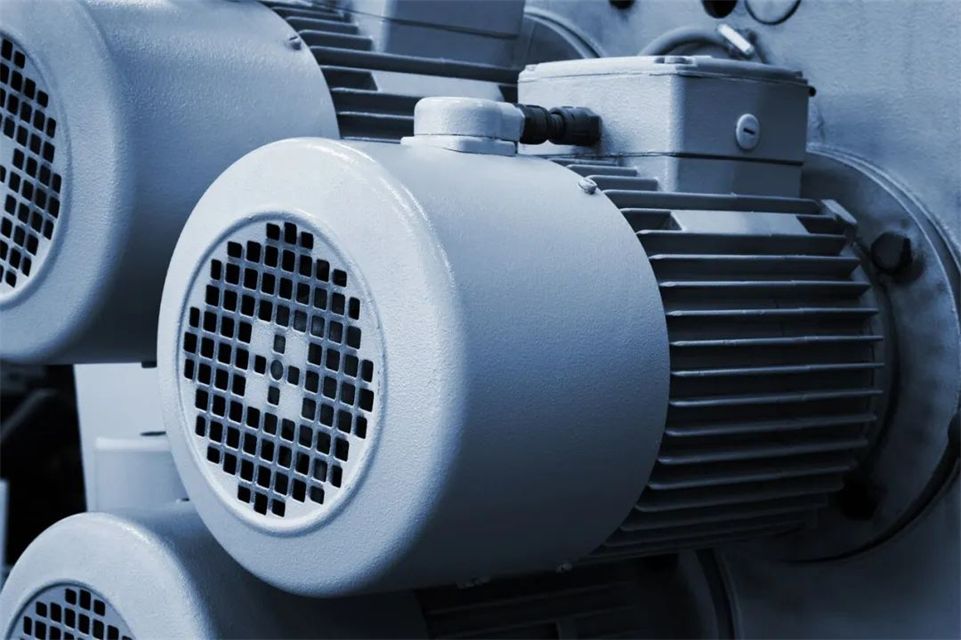

A high-efficiency motor refers to a high-efficiency motor whose efficiency should meet the corresponding energy efficiency requirements. High-efficiency motors integrate new manufacturing processes and new materials perfectly into the core components. The optimized design of the motor coil can effectively reduce the loss of electromagnetic energy, thermal energy, and mechanical energy, and improve the operation efficiency. The motor generates less heat and has a long service life.

Ultra-efficient motors achieve significant energy savings through the use of advanced materials and technologies, improved motor efficiency, the use of frequency conversion control technology and optimized structural design, etc. This not only brings economic benefits, but also conforms to environmental protection policies and is of great significance in promoting sustainable development.

Talking about the ultra-efficient motor, Enneng’s permanent magnet motors are members of it. Enneng is devoted to the research and development of various special high & low voltage Low-speed High-torque permanent magnet motors, constant-speed permanent magnet motors, and special direct-drive permanent magnet motors. We adhere to the quality concept of “Precision Performance”, introduce advanced product design and manufacturing processes at home and abroad, and offer products that meet national and international quality standards. Enneng’s permanent magnet motors are widely used in China famous companies of different fields including gold mines, coal mines, tire factories, oil wells, and water treatment plants have benefited customers for energy saving as well as for environmental protection.

Enneng’s TYB Series Standard Type permanent magnet motor adopts high-efficiency NdFeB permanent magnet, with no excitation loss. Through special rotor structure design, it can greatly reduce iron loss and stray loss, and the efficiency of the whole machine reaches above IE4 standard. The efficiency is increased by 5-10%, and the power factor is improved 10-15% or more. It can maintain high efficiency and power factor in the load range of 20% -120%. The power factor can be 1, and the three-phase asynchronous motor can only reach 0.86.