Small hydro developers face a limited set of bad choices when choosing a generator for small low-head hydro sites, leading to low project efficiencies.

There is a solution from the Wind Industry that can be applied to Hydro Industry – Variable Speed Generators. Increased efficiency from variable speed technology could make many more small hydro sites economically feasible to develop.

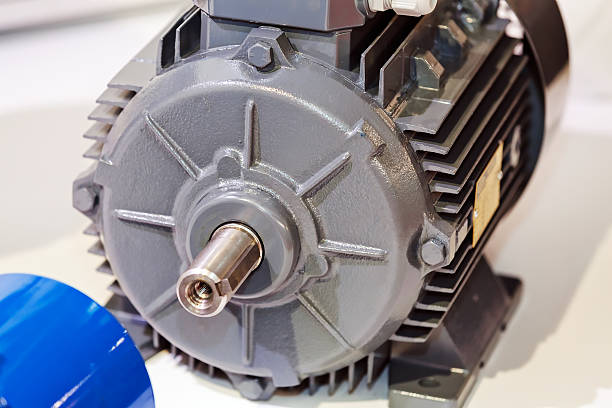

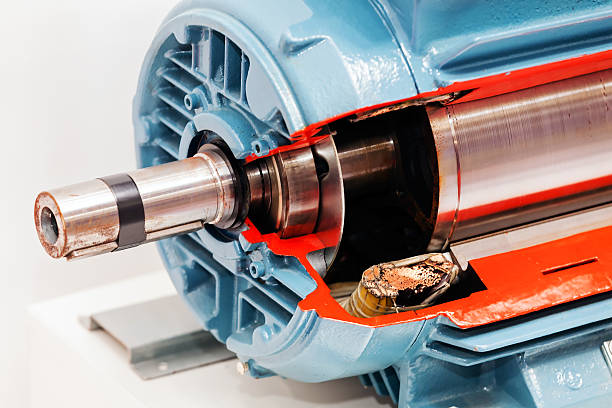

Variable-speed permanent magnet motor is a type of motor characterized by high efficiency, reliability and energy saving, and its rotational speed can be flexibly adjusted according to the load demand. In small-scale low head hydropower station, the application of variable speed permanent magnet motor can give full play to its advantages and improve the operation efficiency and economic benefits of hydropower station.

Advantages:

Due to the use of advanced permanent magnet materials and optimized design, variable-speed permanent magnet motors can reduce energy loss and improve energy conversion efficiency during operation.

In low head hydropower station, the water flow speed and water level change a lot, the traditional constant speed motor often can not adapt to this change, resulting in low efficiency of energy utilization. The variable-speed permanent magnet motor can adjust the rotational speed in real time according to the change of water flow, ensuring that the motor always runs in the best state, thus improving the energy utilization efficiency.

The use of a variable speed generator significantly increased overall project efficiency at small, low-head hydro sites. This technology was adopted by the hydropower industry, efficiency, and energy output is improved at low-head sites, and more small sites became economically feasible to develop.

Thanks to the use of high-quality materials and advanced manufacturing processes, variable-speed PM motors are able to operate stably in harsh environments, reducing failure rates and lowering maintenance costs. This can reduce downtime due to equipment failure and improve power generation efficiency for small-scale low head hydropower plants.

Application:

In small-scale low-head hydropower stations, variable-speed permanent magnet motors can be applied to a number of segments, such as turbine drive and pump control. The operational efficiency and economic benefits of the hydropower station can be further improved through reasonable configuration and optimization of the control strategy.

Products recommendation:

Enneng is a high-tech enterprise intergrating R&D and manufacturing of permanent magnet motors.With more than dozens of patents, Enneng has ranked as “100 Innovative Enterprises” in Qingdao and have been selected as a member of the Qingdao Motor Association. The three-phrase synchronous generators, studied out by Enneng, are widely applied in power systems of marine stations, offshore drilling platforms, land power stations, small hydropower stations, etc. The permanent magnet synchronous generators can be single-unit operation, parallel operation, or grid-connected operation.

Enneng’s permanent magnet synchronous generators have a number of advantages:

① The generator has many poles, which improve the frequency and efficiency, saving the cost of rectifiers and inverters.

② Finite Element Analysis is used when designing the generator, compact structure. Low startup torque, solves the problem of small wind startup, improving wind energy utilization.

③ Leave out the gear increaser, improve the reliability and efficiency of the generator, lower the amount of maintenance.

④ H class insulation, vacuum pressure impregnation.

⑤ Have many structures such as vertical axis, horizontal axis, internal rotor, external rotor, plate type.

⑥ Strong rotors, the generator could achieve high speed.

⑦ Small size, lightweight, high energy density, suitable for special situations.

⑧ Run efficiency throughout the whole speed range, high efficiency.

⑨ Use imported high-speed oil-contained bearings, maintenance-free, high reliability.

⑩ The parameters like voltage, speed, power can be customized. The shape can be changed. Spline shaft, biaxial extension, the flange can be used.

Enneng can make perfect customization for different customers according to different demands. Whatever you need, our experienced engineers shall provide the effective solution as you required. Your demand is always what we pursue!