When delving into the realm of energy conversion, it’s crucial to understand the fundamental principles behind Permanent Magnet Direct Drive Motors. These innovative motors are designed with a focus on maximizing efficiency and performance while minimizing energy losses.

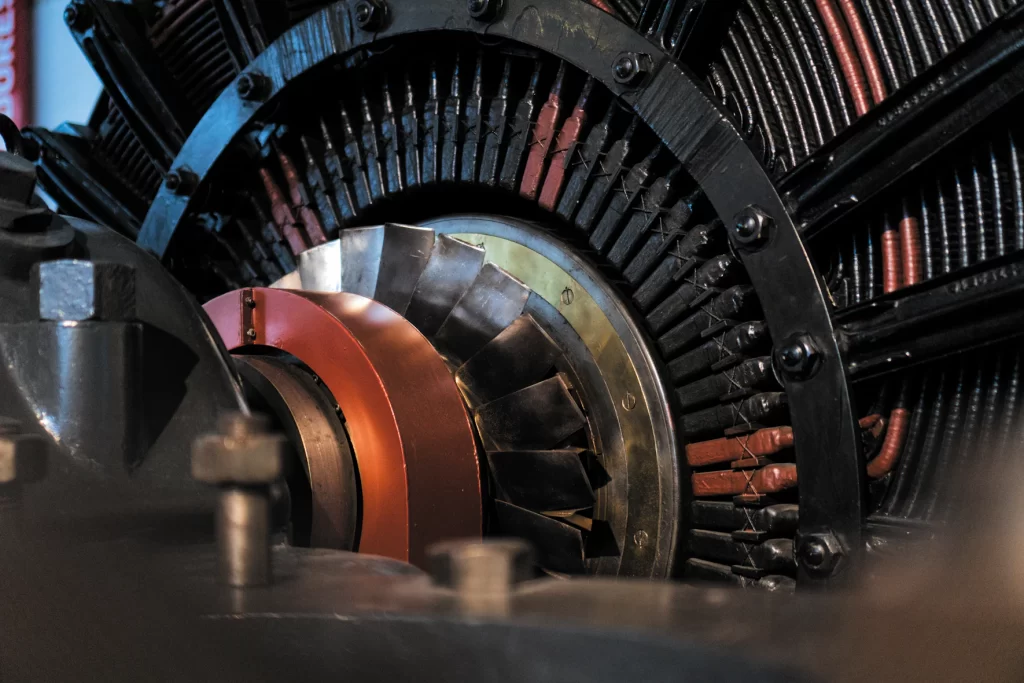

At their core, Permanent Magnet Direct Drive Motors consist of essential components that enable their seamless operation. These include permanent magnets, a rotor, and a stator. The permanent magnets generate a constant motor flux, eliminating the need for the stator field to create one by linking to the rotor. This inherent design contributes to improved energy conversion and operational stability.

Unlike traditional motors that rely on indirect energy conversion processes, Permanent Magnet Direct Drive Motors operate with direct energy conversion mechanisms. By harnessing the power of permanent magnets and synchronous operation, these motors can achieve peak efficiencies ranging from 75% to 82%. This remarkable efficiency is significantly higher than that of conventional shaded-pole induction motors, which typically exhibit an efficiency of approximately 20%.

The key differentiator between Permanent Magnet Direct Drive Motors and traditional counterparts lies in their unparalleled efficiency. For instance, when comparing Permanent Magnet Synchronous Motors (PMS) with shaded-pole induction motors, the former consumes 79% less power and draws 82% less current. Additionally, PMS motors exhibit peak efficiencies far surpassing those of conventional motors.

In terms of performance metrics, it’s evident that Permanent Magnet Direct Drive Motors outshine traditional options across various parameters. The maximum efficiency of an induction motor typically ranges from 90% to 93%, whereas that of a permanent magnet motor exceeds 97%. This substantial improvement in efficiency translates into significant long-term energy savings and reduced greenhouse gas emissions.

By embracing these advanced technologies in energy conversion systems, industries can pave the way for sustainable practices and enhanced operational capabilities.

In the realm of energy conversion, Permanent Magnet Direct Drive Motors offer a multitude of advantages that contribute to their widespread adoption and transformative impact on various industries.

Maximizing Energy Conversion

One of the primary advantages of Permanent Magnet Direct Drive Motors is their unparalleled ability to maximize energy conversion. Research on electric motor technologies has revealed that these motors have undergone significant performance improvements driven by minimum efficiency regulations and increased awareness of energy efficiency importance. By harnessing the power of permanent magnets and synchronous operation, these motors achieve peak efficiencies ranging from 75% to 82%. This remarkable efficiency exceeds that of traditional shaded-pole induction motors, positioning Permanent Magnet Direct Drive Motors as a frontrunner in efficient energy conversion.

Minimizing Energy Losses

Another key advantage lies in the minimization of energy losses. Studies on renewable energy emphasize the importance of reducing energy losses to combat global warming. Permanent Magnet Direct Drive Motors, with their inherent design focused on direct energy conversion mechanisms, significantly reduce energy losses compared to traditional motors. This reduction in losses not only contributes to environmental protection but also leads to substantial long-term energy savings for industries and consumers alike.

Enhanced Power Density

In addition to enhanced energy efficiency, Permanent Magnet Direct Drive Motors boast superior power density compared to traditional motor options. The role of serotonin in PMDD highlights the significance of power density in achieving optimal operational stability. These motors exhibit an exceptional power-to-weight ratio, making them ideal for applications where space constraints are a concern. The increased power density enables more compact designs without compromising performance, thereby revolutionizing the landscape of industrial automation and renewable energy systems.

Optimal Operational Stability

The improved operational stability offered by Permanent Magnet Direct Drive Motors is a result of their seamless integration into various industrial applications. With minimal vibration and noise levels, these motors ensure optimal operational stability even under demanding conditions. This characteristic aligns with the findings from studies on electric motor technologies, which emphasize the importance of stable motor operation for enhanced overall system performance.

The environmental benefits associated with Permanent Magnet Direct Drive Motors cannot be overstated. As highlighted in research on renewable energy, leveraging sources of renewable electricity is crucial for reducing carbon dioxide emissions and combating global warming. By minimizing energy losses and maximizing efficiency, these motors play a pivotal role in promoting sustainable practices across industries while contributing to environmental protection efforts on a global scale.

Qingdao Enneng Motor Co., Ltd. (abbreviated as “ENNENG”) is a high-tech enterprise integrating R & D and manufacturing of permanent magnet motors. With more than dozens of patents, Enneng has ranked as “100 Innovative Enterprises” in Qingdao and we have been selected as a member of the Qingdao Motor Association.

ENNENG is devoted to the research and development of various special high & low voltage Low-speed High-torque permanent magnet motors, constant-speed permanent magnet motors, and special direct-drive permanent magnet motors. We adhere to the quality concept of “Precision Performance”, introduce advanced product design and manufacturing processes at home and abroad, and offer products that meet national and international quality standards. ENNENG permanent magnet motors are widely used in China famous companies of different fields including gold mines, coal mines, tire factories, oil wells, and water treatment plants have benefited customers for energy saving as well as for environmental protection.

As the industrial landscape continues to evolve, the integration of Permanent Magnet Direct Drive Motors has become increasingly prevalent, revolutionizing energy conversion and driving advancements across various sectors.

In the realm of manufacturing and automation, the utilization of Permanent Magnet Direct Drive Motors has led to substantial improvements in operational efficiency and energy conservation. The adoption of these advanced motors in conveyor systems, robotic assembly lines, and precision machining equipment has resulted in enhanced productivity and minimized energy consumption. Studies have shown that the seamless integration of Permanent Magnet Direct Drive Motors in manufacturing processes has significantly reduced power requirements while optimizing production output. This transition towards sustainable motor technologies aligns with industry-wide efforts to embrace eco-friendly practices and reduce carbon footprints.

The impact of Permanent Magnet Direct Drive Motors extends to renewable energy systems, where their superior energy conversion capabilities play a pivotal role in maximizing the efficiency of wind turbines. Research conducted on commercial refrigeration applications highlights the potential economic and environmental benefits resulting from upgrading evaporator fan motors to permanent magnet synchronous (PMS) motors. This evidence underscores the remarkable performance and efficiency of Permanent Magnet Direct Drive Motors in renewable energy applications, further solidifying their position as a cornerstone of sustainable energy solutions.

By leveraging these innovative motor technologies, industries can achieve significant advancements in energy efficiency, operational reliability, and environmental sustainability.

As the demand for sustainable energy solutions continues to rise, the integration of Permanent Magnet Direct Drive Motors plays a pivotal role in enhancing energy conversion across various applications. This section delves into the profound impact of these advanced motors on wind power generators and explores the future trajectory of energy efficiency on a global scale.

The utilization of Permanent Magnet Direct Drive Motors in wind power generators represents a significant leap towards sustainability. Widely used by people around the world underscores the pivotal role of PMDD motors in enhancing energy conversion in new power field, which highlights the adaptability and versatility of these motors in maximizing energy conversion efficiency.

Innovative motor technology, such as PM AC motors and radial flux surface permanent magnet motors, has demonstrated remarkable potential in pump energy for new power appliances. These advancements underscore the transformative impact of PMDD motors in driving efficient energy conversion within the realm of new power.

Innovations centered around Permanent Magnet Direct Drive Motors are poised to redefine the landscape of energy efficiency. Ongoing research and development efforts focus on leveraging novel motor technologies to further enhance energy conversion capabilities. The study mentioned earlier highlights how advancements in motor drive systems using artificial neural network-based maximum power point tracking (MPPT) controllers are set to revolutionize solar-battery powered electric vehicles.

Furthermore, technological advancements such as radial flux surface permanent magnet motors are positioned to drive unprecedented levels of efficiency within new energy appliances. These innovations hold immense promise for optimizing energy conversion processes and fostering sustainable practices across industries.

The widespread adoption and implementation of Permanent Magnet Direct Drive Motors are projected to have a profound impact on global energy consumption patterns. By maximizing energy conversion efficiencies within new energy appliances, these motors contribute to reducing overall power consumption while promoting sustainable energy utilization.

As industries increasingly embrace these advanced motor technologies, there is a tangible shift towards more efficient and environmentally conscious practices. This transition not only aligns with global initiatives aimed at curbing carbon emissions but also sets new benchmarks for enhanced operational reliability and long-term sustainability.

By harnessing cutting-edge motor technologies, industries can pave the way for a future where efficient energy conversion is not just an aspiration but a tangible reality that drives positive environmental outcomes globally.

Recent advancements in permanent magnet direct drive (PMDD) motors have propelled the industry towards a future defined by cutting-edge technological innovations. Industry experts have highlighted key research and development focus areas that are poised to revolutionize the landscape of energy conversion systems. These focus areas encompass a wide range of technological enhancements, including the introduction of motors exceeding IE4 and IE5 efficiency levels. Moreover, standard induction motor technology (IE4) and other innovative solutions such as permanent magnet synchronous motors (PMSM), synchronous reluctance motors (SynRM), and copper rotor induction motors (IE4 and IE5) are at the forefront of research initiatives.

The global PMDD market is set to experience steady growth driven by continuous technological advancements, growing environmental awareness, and the rising need for streamlined operations. Recent technological developments have led to the market introduction of motors exceeding IE4 and IE5 efficiency levels, using standard induction motor technology (IE4) and other technologies such as PMSM, SynRM, and copper rotor induction motors (IE4 and IE5). These advancements underscore the industry’s commitment to enhancing energy conversion efficiencies while embracing environmentally sustainable practices.

In addition to ongoing research efforts, potential breakthroughs in PMDD motor technology are on the horizon. Permanent magnet synchronous motor drives, particularly those leveraging radial flux surface PMAC design, are positioned to redefine energy conversion capabilities across various sectors. This innovative approach expands on traditional PMAC design principles to create a new generation of radial flux surface PMAC motors that exhibit unparalleled energy benefits compared to typical induction motors. The automotive sector has shown significant interest in these advancements due to their potential for high power density, high speed, and exceptional operating efficiency.

The emergence of RF-sPMAC motors represents a pivotal step towards achieving unprecedented levels of energy efficiency within electric motor systems. As industry leaders continue to invest in R&D initiatives focused on PMDD motor technologies, these potential breakthroughs hold immense promise for driving sustainable energy utilization while maximizing operational reliability.

As technological advancements continue to shape the trajectory of PMDD motors, adoption rates are expected to surge across diverse industrial applications. The report equips businesses with valuable foresight by highlighting emerging trends and innovations in the PMDD market. Leading companies operating in this space are spearheading initiatives aimed at integrating advanced motor technologies into their operations, signaling a widespread shift towards embracing efficient energy conversion solutions.

Industry experts emphasize that technologically mature solutions such as PMSM drives and SynRM technologies can be scaled up quickly, paving the way for rapid adoption rates within industrial settings. The increasing adoption of these advanced motor technologies underscores a collective commitment towards achieving enhanced energy efficiencies while reducing overall power consumption.

The integration of PMDD motors is poised to catalyze transformative changes within industries reliant on efficient energy conversion systems. Recent market trends indicate a growing preference for permanent magnet synchronous motor drives due to their superior performance characteristics. These transformative shifts reflect an industry-wide recognition of the substantial savings identified from energy-efficient motor systems.

Furthermore, as businesses prioritize environmentally conscious practices alongside operational excellence, the widespread adoption of advanced PMDD motor technologies is set to redefine industry standards while fostering sustainable operational frameworks.

By aligning with emerging market trends and harnessing innovative breakthroughs in PMDD technology, industries can position themselves at the forefront of efficient energy conversion while contributing significantly towards global sustainability efforts.