Rare earth permanent magnet motor is a new type of permanent magnet motor appeared in the early 70’s, due to the excellent magnetic properties of rare earth permanent magnet materials, it is no longer needed after magnetization of the external energy to establish a strong permanent magnetic field. Used to replace the traditional electric excitation motor, rare earth permanent magnet motor has not only high efficiency, the structure of a simple and reliable operation, but also small size and light weight. Both can achieve the traditional electric excitation motor is incomparable to the high performance (such as special high-efficiency, special high-speed, special high response speed), but also can be made to meet the specific operational requirements of special motors, such as elevator traction motors, automotive motors and so on. Rare-earth permanent magnet motors combined with power electronics and microcomputer control technology, more motor and drive system performance to a new level. In order to improve the performance and level of the supporting technology and equipment, is the motor industry to adjust the industrial structure of the important direction of development.

Rare earth permanent magnet motors have a wide range of applications, almost all over the aviation, aerospace, national defense, equipment manufacturing, industrial and agricultural production and daily life in various fields. It includes permanent magnet synchronous motors, permanent magnet generators, permanent magnet DC motors, brushless DC motors, AC permanent magnet servo motors, permanent magnet linear motors, special permanent magnet motors and related control systems, covering almost the entire motor industry.

Qingdao Enneng Motor Co., Ltd. (abbreviated as “ENNENG”) is a high-tech enterprise integrating R&D and manufacturing of permanent magnet motors. With more than dozens of patents, Enneng has ranked as “100 Innovative Enterprises” in Qingdao and have been selected as a member of the Qingdao Motor Association. Enneng would like to jointly work with users all over the world to focus on energy-saving solutions to benefit our society and people.

On November 22, 2021, the Ministry of Industry and Information Technology, the General Administration of Market Supervision and Regulation jointly issued the “Motor Energy Efficiency Improvement Plan (2021-2023)”, which puts forward that by 2023, the annual output of energy-efficient motors will reach 170 million kilowatts, and the proportion of energy-efficient motors in service will reach more than 20%, realizing an annual power saving of 49 billion kilowatt-hours. The document clearly mentions that “for fans, pumps, compressors, machine tools and other general-purpose equipment, encourage the use of level 2 energy-efficient motors and above. For variable load operation conditions, promote the use of permanent magnet motors with frequency conversion and speed regulation of grade 2 energy efficiency and above”.

According to the 2013 version of “Permanent Magnet Synchronous Motor” standard, the existing permanent magnet motors are distributed in the range of Grade 1 and Grade 2 energy consumption; combined with the “Motor Energy Efficiency Limit Value and Energy Efficiency Grade” (GB 18613-2020) and “Motor Energy Efficiency Improvement Plan”, only some high-performance NdFeB rare-earth PM motors can reach more than 95% of the efficiency of the first-grade energy consumption standard (corresponding to IE5), while the rest of rare-earth PM motors belong to the second-grade energy consumption standard. Currently, rare-earth PM motors can save more than 10% of electricity and increase the efficiency to more than 95%. Using rare earth permanent magnet synchronous motor, reactive power saving rate of up to 85%, active power saving rate of up to 23% to 25%, power saving effect is remarkable.

Industrial motors are the largest area of social power consumption. In 2020, China’s motor ownership of about 4 billion kilowatts, the total power consumption of about 4.8 trillion kWh, accounting for 64% of the total power consumption of society, of which the total power consumption of industrial motors 3.84 trillion kWh, accounting for about 75% of the industrial power consumption. The energy efficiency of industrial motors improve every 1% can be an annual savings of about 38.4 billion kWh of electricity. If the energy efficiency improve 3%, annual savings of electricity is equal to the annual power generation of The Three Gorges. The State Council issued the “2030 Carbon Peak Action Program”, which highlights the promotion of energy conservation and efficiency of key energy-using equipment, focusing on motors, fans, pumps, compressors, transformers, heat exchangers, industrial boilers, and other equipment, and comprehensively improve energy efficiency standards.

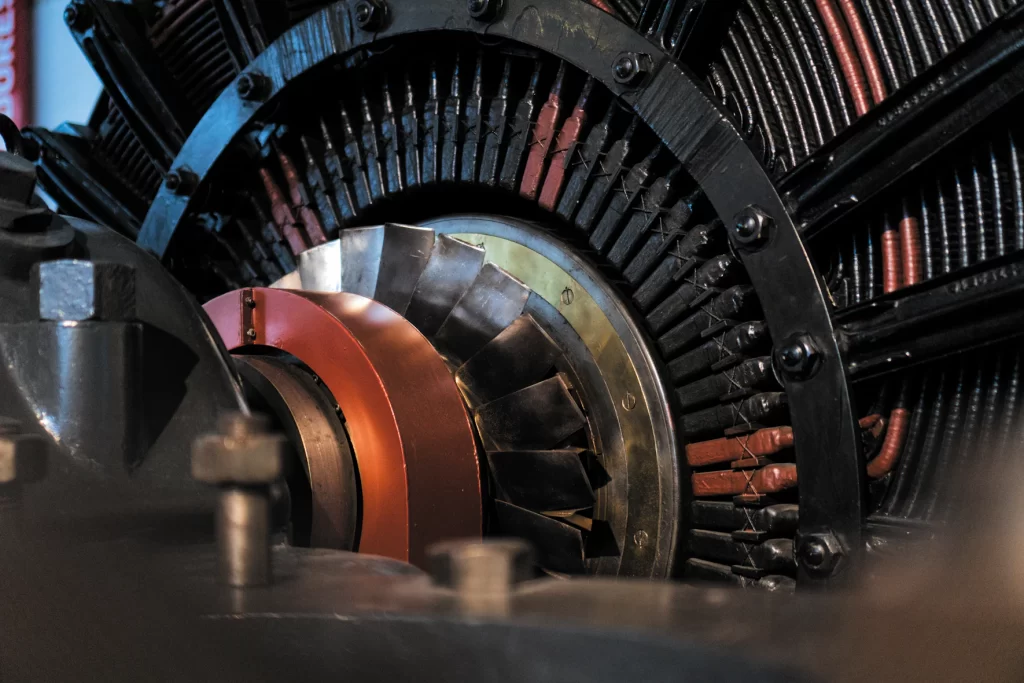

Energy-efficient motor refers to the general standard motor with high efficiency (in line with the new motor energy efficiency standards above the second level) of the motor, in May 2020, China announced the latest motor energy efficiency standards “GB18613-2020 motor energy efficiency limit and energy efficiency level”, the standard was formally implemented on June 1, 2021, the motors below the energy efficiency IE3 (international standard) will be mandatorily discontinued. The types of motors include three-phase asynchronous motors, traditional asynchronous motors, etc. Although traditional asynchronous motors can improve the efficiency of the motors by increasing the materials, due to the basic principle of its operation, there is a ceiling for the improvement, and this improvement is very difficult. Therefore, part of IE4 and IE5 energy-efficiency motors prefer to use permanent magnet mode, used by permanent magnet synchronous machines.

Energy saving: Unlike asynchronous motors, the rotor of permanent magnet motors does not need excitation current, which saves energy by about 15%-20%.

High efficiency: The efficiency of permanent magnet motors is 2-19 percentage points higher than that of traditional motors.

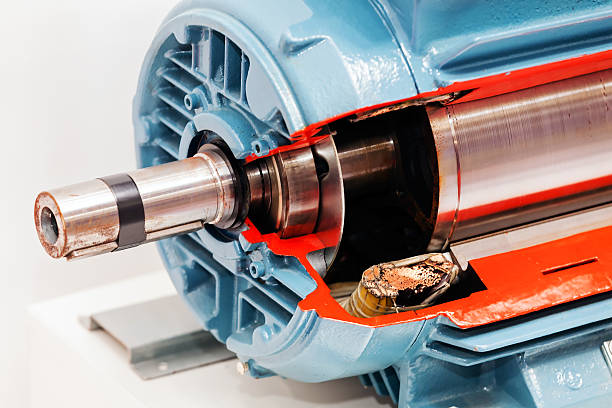

Simple structure and low failure rate: The permanent magnet motor eliminates the structure of excitation winding and pole core, so it does not need the regulation of electric excitation, which saves the excitation power supply and the loss of electric excitation. At the same time, the permanent magnet motor generates a magnetic field through rare earth permanent magnets, thus eliminating the commutation of slip rings and brushes in the conversion of magnetic poles, making the overall structure more simplified. In addition, the permanent magnet motor also avoids the defects of commutation device and excitation winding that are prone to failure in long-term operation, which greatly improves the reliability of the motor. These features make permanent magnet motors simpler and more efficient in the design and manufacturing process, while also reducing the complexity of maintenance and repair.

Long life: The rotor of permanent magnet motor adopts embedded sealed structure, which is conducive to reducing the friction and oxidation during rotation, and improving the stability and life of the motor.

Replacement of rare earth permanent magnet motor recycling cycle of about 1-2 years, the economic benefits are actually very obvious. According to the literature “about the application of rare earth permanent magnet motor in thermal power plant”, 110kw circulating water pump, for example, rare earth permanent magnet power saving rate of about 8.21%, according to the annual operation of 7,000h calculations, you can save electricity 63,200,000 kwh per year, according to the calculation of 0.6 yuan/kwh, you can save electricity costs of 37,930 yuan per year, the water pump selling price of about 71,000 yuan, the recovery cycle of about 1.87 The payback cycle is about 1.87 years. Different application areas of 15% -20% or so of the power saving rate, the recovery cycle will be even shorter.

Nature of magnetic field

Permanent magnet motors do not need external energy to maintain their magnetic field after being made; ordinary motors need electric current to have a magnetic field.

Widely applicable occasions

Ordinary motors need to drive the gear mechanism to achieve high torque, while rare earth permanent magnet motors can replace the gear mechanism to achieve direct drive.

Good running stability

Compared to other types of motors, permanent magnet (PM) motors run smoother and produce less noise and vibration. This contributes to the comfort and reliability of equipment operation, especially in noise and vibration sensitive environments.

High power density and efficiency

Compared with ordinary motors, permanent magnet synchronous motors have high power density, which mainly refers to the small size of permanent magnet motors and high power generation or output. Compared with ordinary motors energy saving reaches 20%-40%. The rotor structure of permanent magnet motor and ordinary motor is different, permanent magnet motor rotor is installed with permanent magnet poles; ordinary motor rotor is installed with excitation coil, which requires current flow to have magnetic field. With permanent magnet motors, power can be saved at any point of speed, and this advantage is especially obvious at lower speeds. Most modern submarines use large-diameter, low-speed, 7-bladed, large side-slope propellers or pump-jet propellers, which have low rotational speeds and high propulsive efficiency. Moreover, the submarine in the underwater more low-noise speed maneuvering, so that this advantage of permanent magnet motors to be better embodied and play.

Small size, light weight, low temperature rise

Permanent magnet synchronous machine structure is simple, due to the use of high-performance permanent magnet material to provide magnetic field, so that the air gap magnetic field of the permanent magnet motor is greatly enhanced compared to ordinary motors, while the volume and weight of the permanent magnet motor is greatly reduced compared to ordinary motors, the size and shape of the motor is also flexible. No electrical excitation of the rotor means no loss of heat, therefore, permanent magnet motors generally have a very low temperature rise.

Lower failure rate

Permanent magnet motors use high-performance permanent magnet materials as the magnetic field source, making the motor have more stable magnetic field characteristics. Compared with the electric excitation or electromagnet used in traditional motors, permanent magnet materials are less susceptible to external environmental influences, and therefore can maintain stable performance for a long period of time. Secondly, the structure of pm motors is relatively simple, without complex collector rings and brush devices, reducing potential points of failure. Collector rings and brushes in conventional motors often fail due to wear and tear or poor contact, while permanent magnet motors avoid these problems.

High starting torque and good performance

The magnets in permanent magnet motors generate a stable magnetic field, which provides the motor with a strong starting torque. Compared to conventional motors, permanent magnet motors can quickly reach a high torque at startup, allowing the equipment to quickly enter normal operating conditions.

The service life of permanent magnet motors is generally 15-20 years, and the length of the motor’s service life depends mainly on the user’s maintenance. In addition, the environment in which the permanent magnet motor is used is good or bad, and the motor is subjected to electricity, magnetism, heat, vibration and other factors in use, all of which will affect the life of the permanent magnet synchronous motor.

General magnets have a service life, when used for a certain number of years, the magnetism will be weakened, but neodymium-iron-boron permanent magnet material magnetic change over time is very small, rare-earth permanent magnets in the design of the motor life (10-20 years) magnetic decay <3%, in the existing design of the motor and electronic control technology, for the overall performance of the motor has very little impact.

As a China leading permanent magnet motor supplier, Enneng can make perfect customization for different customers according to different demands. Enneng’s main products include TYB Series Standard Type Permanent Magnet Motor, TYDP Series Direct Drive and Gearless Motor, and FTYP series of three-phase permanent magnet AC synchronous motors, etc. Whatever you need, our experienced engineers shall provide the effective solution as you required. Your demand is always what we pursue!