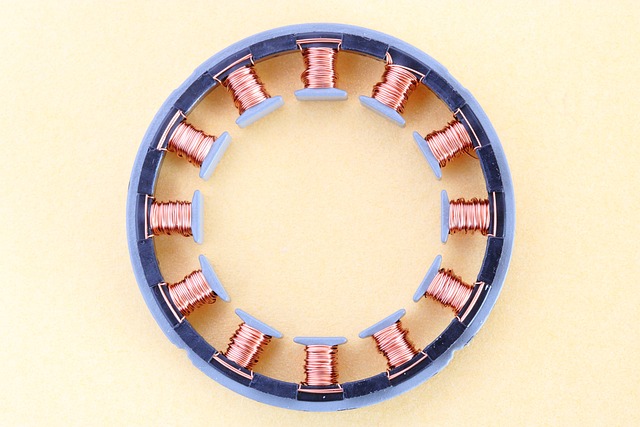

Permanent magnet synchronous motor PMSM forms the heart of modern power transmission technology, therefore contributing a great deal to those areas where the technology has been put into application: ranging from electric vehicles and wind energy conversion to industrial automation. Being its part, it is not possible to get rid of the motor; therefore, the influence that the stator winding provides becomes deep-rooted over the general performance of the PMSM.

Structural characteristics of the stator winding and its impact on the performance of the motor

Design is considered one of the most important aspects in the development of a motor that realizes good performance. Proper conceptualization of the structural nature of a stator winding supports efforts at optimization in terms of performance and reliability. Key factors influencing such are design and performance capability and will thus be discussed as follows: wire material, cross-sectional area, number of turns, current density, slot type, and slot fullness.

Wire Material and Cross-Sectional Area

Common Materials: Copper and Aluminum

Cross-Sectional Area

Number of Turns and Current Density

Number of Turns

Current Density

Slot Type and Slot Fullness

Slot Type

Slot Fullness

Conclusion

Generally speaking, the designs include features of wire material, the area of cross-sections, the number of turns, the density of current, the slot type, and itfullnessll vital features since influence from each of them strongly hits the motor performance as well as the reliability. Besides, to achieve high efficiency and very powerful while operational, the optimization of each should be considered.

Electromagnetic properties of the stator winding and its impact on motor performance

The stator winding plays a very important role in the generation of the rotating magnetic field in the motor. Its electromagnetic performance has a great influence on the torque output, efficiency, and smoothness of operation of the motor.

Magnetic field distribution: the magnetic field of the winding is to couple with the magnetic field of the permanent magnet to produce a steady electromagnetic torque. Reasonable designing of the winding can optimize the distribution of the magnetic field, reduce the harmonic content,t, and lower the torque pulsation to improve the smooth operation of the motor.

Inductance and resistance: the inductance of the winding influences the dynamic response and the waveform of current in the motor. With larger inductance, it can restrain the abrupt variation in current and electromagnetic interference effectively. However, that may raise the electrical time constant of the motor. The resistance accounts for the energy of the winding into heat. Smaller resistance will promote the improvement of motor efficiency.

Thermal performance of the stator winding and its impact on motor performance

Thermal performance concerning stator windings is a very critical factor in normal operation and motor reliability. Proper thermal management can avoid such problems as aging of the insulation materials, wire meltdown, and enhancing efficiency and service life for motors.

Temperature Rise

Heat Dissipation

Thermal Class of Insulation Materials

Electrical Strength

Mechanical Strength

Selection and Processing of Insulation Materials

Generally speaking, on the stator winding itself, thermal management is subject to proper governance in temperature rise while sustaining effectiveness in aspects related to dissipating heat. The selection and treatment of insulation materials for withstanding thermal stress will also affect electrical and mechanical strengths. Motor winding thermal management will optimize its efficiency, reliability, and durability with greater effectiveness.

Stator winding manufacturing process and its impact on motor performance

In their process of making them, quality affects stator winding and in general influences motor performance.

Winding process: The process of winding should be such that wire is nicely and tightly packed to avoid crossing over each other and, misalignment amongst other phenomena; while doing so, the tension of winding shall be moderate to avoid damage to the insulation or turn-to-turn shcircuitscuit dua e to a too tight or too loose wire.

Insulation treatment: To improve the electric and mechanical strength, insulation treatment will be conducted after winding. The general insulation treatments are dipping paint and wrapping insulation tape, etc. During the insulation treatment process, the thickness of insulation should be uniform to avoid wasting insulation material; besides, the insulation layer needs to fit closely onto the wire.

Quality inspection: the finished windings should be carried out in quality testing, which includes appearance inspection, measurement of size, and electrical performance test. The essence of quality testing lies in whether the winding can satisfy the design requirement and protect the whole performance of a motor.

Conclusion

The stator winding relates intimately to the performance of the permanent magnet synchronous motor. As efficiency, power density, smoothness of operation, and reliability all depend on the optimum design of the winding and of the manufacturing process, this is where all these aspects can achieve an important improvement thanks to a well-considered choice of materials. While huge scientific and technological progress is continuously made in the future, faster development of the new energy sector will be conducted deeper and wider into relationships between the stator windings and the performance of permanent magnet synchronous motors.

ENNENG is a high-tech company that has professional R&D of Permanent Magnet Synchronous Motors. The motors the company has designed can be high and low voltage, with low speed and high torque. The motors by the company are found in nearly every industry, which may include gold mines, coal mines, tire factories, oil wells, and water treatment plants.

Compared to traditional motors, ENNENG PMSM motors have much higher energy efficiency; thus, they save customers much in energy. It also has a wide range of speeds and maintains low speeds that will make the motors very suitable for applications needing highly precise control of the speed. Besides, it has a compact design with low mechanical noise and an extremely low failure rate, thus being virtually maintenance-free.

Certain clear benefits of PMSM motors by ENNENG are industry-specific. Consider its application to the textile industry for high-precision speed adjustment, with energy savings across a wide speed range. In the industry responsible for machinery for rubber tires, PMSM motors applied to such machinery introduce tremendous energy savings and a remarkable advance in maintenance-free service.

ENNENG PMSM motors are applied widely in the area of wind power and water generation; hence, they guarantee reliable power at high efficiency. This motor does not need gearboxes or other devices in the plastic extruder industry; thus, it simplifies the structure of the extruder, thereby reducing maintenance.

The ENNENG permanent magnet synchronous motors generally grant reliability in many industries; such kinds of motors guarantee energy efficiency with cost-effectiveness. Thus, the companies prefer such a type of motor with advanced design and technology for appropriate energy savings with better efficiency and sustainable production.