Permanent magnetic materials, referred to as “hard magnetic materials,” are substances that retain consistent magnetic properties once magnetized. In practical applications, these materials operate within the demagnetized region of the hysteresis loop’s second quadrant following thorough magnetic saturation and magnetization. Alnico permanent magnetic alloys, ferrochrome cobalt permanent magnetic alloys, permanent magnetic ferrites, rare earth permanent magnetic materials, and composite permanent magnetic materials are commonly utilized types of permanent magnetic materials.

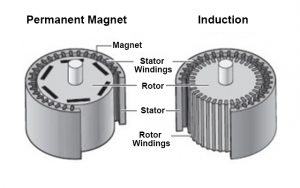

Permanent magnet motors use permanent magnets to generate the motor’s magnetic field. It operates without the need for an excitation coil or an excitation current. Permanent magnet motor has high efficiency and simple structure, it is a good energy-saving motor. With the introduction of high-performance permanent magnet materials and the rapid development of control technology. Permanent magnets and permanent magnet motors will become more widely used.

Permanent magnets and permanent magnet motors are relevant to many aspects of our lives. When operating permanent magnets or permanent magnet motors, there are a number of considerations that we must pay attention to in order to ensure that they work safely and consistently to maximize their effectiveness.

1.Design

■The values in the table of magnetic properties are characteristic values under specific conditions and are not guaranteed values in use. Different magnet size, magnetic circuit structure, working environment and other factors may make the performance of magnets in use can not reach the characteristic value. Please check the actual usage conditions of the samples before designing.

■Magnets may be demagnetized due to high temperatures. Be sure to check the operating temperature of the environment in which the magnets are assembled or used at the time of design. Select the appropriate material carefully and take necessary precautions.

■Using or storing magnets in harsh environments such as corrosive environments, high temperatures and humidity, acid-base organic solvents, etc., may cause the magnets to rust and corrode. This may result in reduced magnetic properties or even breakage. Please take precautions when designing magnets. So it is essential to store magnets away from harsh environments such as corrosive, high temperature and humidity, acid-base organic solvents.

■Since magnets are hard and fragile, if used in applications subject to strong vibration or shock, they may break or lose their magnetic properties. Please take care when designing them.

■When magnets are used in high-speed rotating applications such as motors, if the fixing measures are not in place, the magnets may fall out and cause damage to the equipment. Please take care when designing them.

■Inadequate mechanical assembly action or mechanical structure during assembly processing may prevent the assembly magnet from being held stably and efficiently. Please take care when designing them.

2.Assemble

■After magnetization, the magnets have a strong suction force, which, if operated improperly, may cause the operator’s fingers to be caught between the magnets or between the magnets and the iron parts, resulting in an accidental injury.

■Due to the mutual suction force of magnets, improper operation may cause high-speed collision between magnets, resulting in broken magnets and splashing of broken pieces. This can cause injury accidents and due care should be taken.

■Magnets can attract iron powder, iron parts or magnet fragments, which can affect the use or assembly effect. Be careful to clean the environment in which the magnets are used.

■When bonding the magnets, please take care to avoid adhering oil, dirt, and other foreign matter to the bonding surface, which may cause a decrease in the bonding strength of the magnets.

■Before using an adhesive to bond magnets to each other or between magnets and yokes, make sure that the bonding is reliable. Please check the type of adhesive, bonding conditions, durability, dosage, and bonding strength at the time of design.

■Secondary processing of magnets such as drilling, cutting, and grinding may result in heat generation, reduction of magnetic properties, cracking, and peeling of plating. Therefore, secondary processing of magnets should be avoided as much as possible.

3.Store

■Keep the product in a safe place to prevent the magnets from being damaged or cracked due to accidental dropping or crushing.

■Please store the product in a dry place to avoid rusting of the magnets due to humid environment.

4.Other

■Do not place the magnet near magnetic recording media such as magnetic cards, magnetic tapes, prepaid cards, tickets, etc. to avoid damage to the recorded information.

■Do not place magnets near electronic equipment to avoid possible interference effects of magnetic fields on circuits, etc.

1.Magnetic circuit structure and design calculations

In order to give full play to the magnetic properties of various permanent magnet materials, especially the excellent magnetic properties of rare-earth permanent magnets, to manufacture cost-effective permanent magnet motors, it is not possible to simply apply the traditional structure and design calculation methods of permanent magnet motors or electrically excited motors. A new design concept must be established to reanalyze and improve the magnetic circuit structure. With the rapid development of computer hardware and software technology, as well as electromagnetic field numerical calculations, optimization design and simulation technology and other modern design methods continue to improve, through the joint efforts of the electrical machinery academic and engineering circles, has made breakthroughs in the design theory of permanent magnet motors, computational methods, structural processes and control technology and formed a combination of numerical calculations of the electromagnetic field and the equivalent magnetic circuit analytical solving a complete set of analytical research methods and computerized research methods. A set of analysis and research methods and computer-aided analysis, design software. This series of technology is being continuously improved.

2.Control issues

Permanent magnet motors do not require external energy to maintain their magnetic field, but they also make it extremely difficult to externally regulate and control their magnetic field. Permanent magnet generators are difficult to externally regulate their output voltage and power factor and permanent magnet DC motors can no longer regulate their rotational speed by changing the excitation. These make the scope of application of permanent magnet motors is limited. However, with the rapid development of power electronics and control technology such as MOSFETs, IGBTs, etc., most PM motors can be applied without magnetic field control but only armature control. The design needs to combine the three new technologies of rare-earth permanent magnet materials, power electronics and microcomputer control to make the permanent magnet motor operate under brand-new working conditions.

3.Irreversible demagnetization

If improperly designed or used, permanent magnet motors may be irreversibly demagnetized, or called demagnetized, at too high (for powerful magnets) or too low (for ferrite permanent magnets) temperatures, under the action of armature reaction produced by inrush currents, or when subjected to severe mechanical vibration. This can make the motor performance reduced, or even unusable. Therefore, it is necessary to research and develop methods and devices suitable for motor manufacturers to check the thermal stability of permanent magnet materials, but also to analyze the demagnetization resistance of different structural forms, so as to ensure that permanent magnet motors are not demagnetized by adopting appropriate measures in the design and manufacture.

4.Cost issues

Ferrite permanent magnet motors, especially miniature permanent magnet DC motors, are extremely widely used because of their simple structural process, relatively light weight, and generally lower total cost than electrically excited motors. As rare earth permanent magnets are still relatively expensive, the cost of rare earth permanent magnet motors is generally higher than that of electrically excited motors. This shortcoming this needs to be compensated by its high performance and savings in operating costs. In some applications, such as voice coil motors for computer disk drives, the use of NdFeB permanent magnets results in improved performance and a significant reduction in volume and mass. This leads to a reduction in total cost instead. In the choice of which permanent magnet motors need to be used according to the specific use of occasions and requirements, performance and price comparisons to determine the trade-offs, but also the structure of the process of innovation and design optimization in order to reduce costs.

Technology is the friend of mankind, technology serves mankind, and mankind enjoys the convenience brought by technology. As an emerging technology that started only less than a hundred years ago, permanent magnets have greatly contributed to the development of human science and technology. Therefore, in the daily transportation, storage, assembly and shipping of permanent magnets and permanent magnet motors, we should pay more attention to these precautions so that permanent magnet technology can help us better.