Permanent magnet synchronous frequency conversion compressor is a kind of air compressor using permanent magnet synchronous motor drive, frequency conversion speed regulation. This compressor gives full play to the advantages of permanent magnet synchronous motor and frequency conversion technology, with high efficiency, low energy consumption, low noise, low vibration and other advantages.

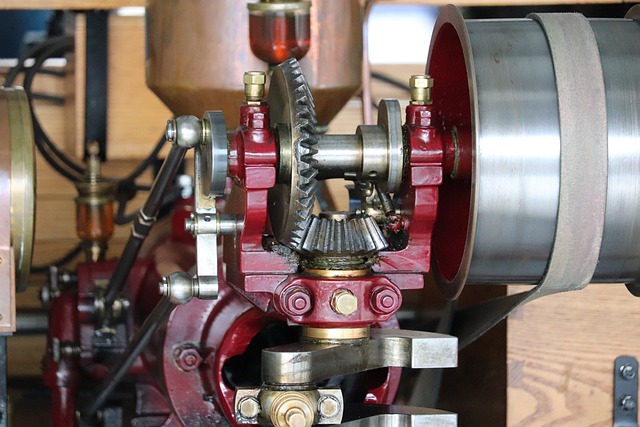

In terms of structure, permanent magnet synchronous frequency conversion compressor is mainly composed of motor and compressor. The motor is a permanent magnet synchronous motor with a rare earth permanent magnet material on its rotor, which can generate a strong magnetic field and thus drive the rotor to rotate efficiently. The compression mechanism, on the other hand, consists of two single-stage compressors, a high-pressure stage and a low-pressure stage, which are connected by an intercooler to reduce the temperature of the gas entering the low-pressure stage compressor.

In the principle of operation, the motor-driven high-pressure compressor compresses the gas to a certain pressure and then passes through the intercooler into the low-pressure compressor, where it is compressed again. Eventually, the compressed gas passes through condensers, dryers and other equipment to reach the required pressure and temperature.

Due to the use of permanent magnet synchronous motor, this compressor equipment runs more smoothly and with lower noise. Meanwhile, the simple structure and small size of the permanent magnet synchronous motor make the whole equipment compact and easy to install and maintain. In addition, the permanent magnet frequency conversion screw air compressor is also characterized by intelligence. By equipping with advanced control system, remote monitoring, diagnosis and troubleshooting of the equipment can be realized, which improves the reliability and safety of production.

Permanent magnet synchronous inverter compressors are widely used in the fields of iron and steel, electric power, metallurgy, shipbuilding, textile, electronics, chemical industry, petroleum, mining, light industry, machinery manufacturing, papermaking and printing, transportation facilities, foodstuffs, casting and spraying, marine terminals, military science and technology, automotive industry, aerospace, and infrastructure. In these industries, permanent magnet synchronous frequency conversion compressor with its high efficiency, energy saving characteristics, to meet the needs of a variety of manufacturing industries for air compression, become an indispensable and important equipment in the factory.

Enneng is a China leading permanent magnet motor supplier. Enneng’s permanent magnet motors are widely used in China famous companies of different fields including gold mines, coal mines, tire factories, oil wells, and water treatment plants. we now introduce Energy-saving Permanent Magnet Motors with our VFD models which decreases energy consumption substantially to save even more energy as well as money.

Enneng permanent magnet motor uses a motor with a temperature rise lower than 60K, ensuring the compressor has a longer life. The motor is made from rare earth permanent magnet material, which requires a low current due to its high magnetic strength and load torque during motor start-up and operation. The combined use of this motor and permanent magnet rotor achieves soft-start and electricity saving of up to 50%, with the motor’s efficiency up to 10%-15% when compared with an asynchronous motor with the same specifications, thus avoiding a powerful mechanical impact on the compressor under the motor’s full pressure start and ensuring a longer service life.