Motors find a wide application in modern industrial automation. Precise control of the speed and precise control of the motor is a key issue to achieving efficiency, precision, and reliability in mechanical movements.

Speed control and torque accuracy at each stage would not only be conducive to but would also ensure stability in production. With motors running precisely in terms of speed and torques, the entire system comprising the production process would respond with consistency and reliability in performance. Such stability decreases perturbations and reduces variations in production output. As a result of consistent performances of motors, breakdowns will fall while maintenance is reduced, in turn contributing toward smoother and predictable operations.

The quality of the final product depends critically on the quality of control of both motor speed and torque. In manufacturing processes like machining, good control of the motor directly influences the efficiency of the cut and accuracy of the machined parts. Poor performance of the motors results in defects in products, reducing dimensional accuracy and surface finish. Thus, precise motor control is important to realize quality products with customer satisfaction.

Inaccurate control of motor speed and torque may lead to several adverse effects. It may lead to increased tool wear in machining operations, thus reducing the lifespan of expensive equipment. Besides, it can lead to deviations in the manufacturing process, leading to product defects and increased scrap rates. These inefficiencies not only raise production costs but also damage the overall productivity and profitability of the manufacturing operation. Also, low-quality motor control can cause frequent breakdowns and maintenance that may result in considerable downtime, thus affecting the overall throughput of the production line.

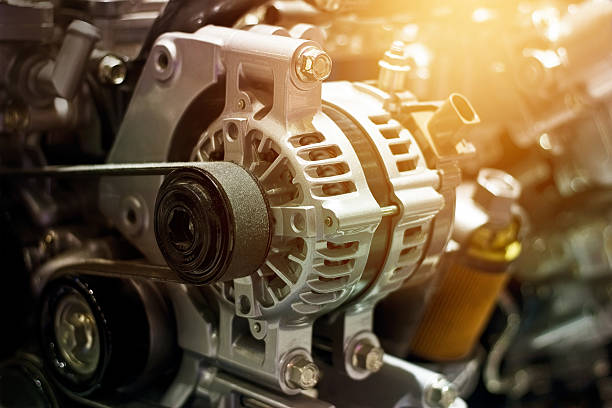

In DC motors, speed and torque control are usually performed by adjusting the input voltage or current. This means that increasing or decreasing the voltage applied to the motor increases or decreases its speed, respectively. Similarly, by changing the current, it is possible to change the torque output of the motor. This makes for easy and efficient control of performance, thus making DC motors applicable in areas that need precise adjustments in speed and torque.

To drive and operate the performance, speed, and torque control of the AC motor mean input adjustments of frequency and voltage. Therefore, changing in supply power frequency may handle the rotational speed of such motors. Variably altering input voltage modifies motor torque produced. The change in control is normally widely exploited in frequency variable drives when the precision of AC motor’s performance ought to be executed: running them well in industrial jobs that abound.

Since real-time control is critical, it makes sense to monitor the motor’s variable speed and torque. Sensors are employed to monitor the operating variables of a motor, such as speed, torque, and position. This is delivered to controllers that compare actual values with desired set points. The controllers, based on this comparison, make necessary adjustments in the input voltage or current such that the motor operates within specified parameters. This continuous feedback loop allows for accurate and responsive control of motor performance.

Closed-loop mechanisms are widely used for precise control of motor speed and torque. In a closed-loop system, the motor speed and torque are measured continuously and compared to set values. The difference or error between the values becomes an input to modify the voltage or current input to the motor. Such minute adjustments by feedback control algorithms, like Proportional-Integral-Derivative, are part of this process to make the motor performance match the specification. Closed-loop control ensures very high accuracy and stability for motor operations, hence is considered in many industrial applications.

In feedback control, sensors continuously monitor the motor parameters, such as speed and torque. These real-time measurements are compared with preset values, and adjustments are made to the input signals to minimize discrepancies, hence making the motor operate as desired.

PID is a classic closed-loop control algorithm. It readjusts the motor performance through three parameters: proportional, integral, and derivative. In this approach, immediate correction of the error is balanced by overall stability and response time.

Fuzzy control is a method that employs fuzzy logic to deal with the uncertainties in motor control. By translating expert knowledge into fuzzy rules, this approach can make intelligent adjustments in motor speed and torque, accommodating variations that traditional methods might not efficiently address.

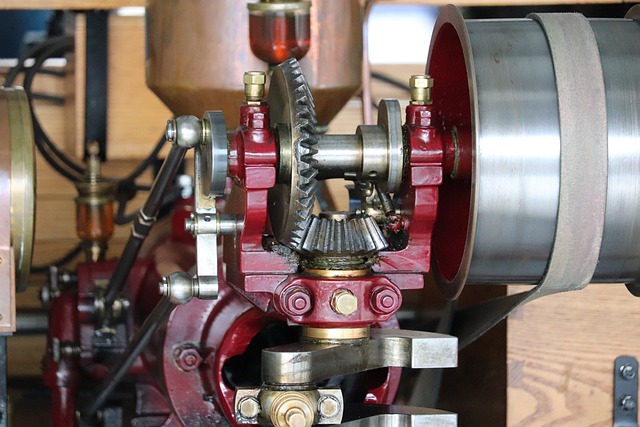

Multivariable decoupling control addresses interdependencies between several inputs against several outputs. By decoupling, each aspect of the motor performance can be independently controlled by the control system, which increases precision and responsiveness.

The vector control is accomplished by magnetic field orientation for control of the motor speed and torque. The magnetic field is aligned with the rotor in such a manner that allows efficient and precise control of motor dynamics.

In vector control, the motor current is decomposed into two components: torque-producing and magnetizing currents. Controlling these components separately allows for precise adjustments to the motor’s speed and torque.

Coordinate transformation techniques convert the three-phase motor currents into two-phase currents. This simplification allows for easier management and control of the motor’s performance precisely.

Advanced vector control is very often complemented by nonlinear control methods as sliding mode control may improve the dynamic response and reduce the steady-state errors, hence enhancing the accuracy of motor control.

The main issues of the DTC strategy deal with real-time monitoring of the magnetic flux and torque produced by the motor. Real-time measurements ensure that their respective optimal values are obtained through appropriate corrections.

DTC controls the motor’s flux and torque directly using voltage space vector modulation. This method follows very effective tracking and, therefore, precise control by changing the motor’s voltage vectors.

For instance, modern adaptive control methods are often added to DTC to further enhance the robustness of the motor and, in turn, its anti-interference capabilities, ensuring stability of operation and precision under most operating conditions.

The technological development of motor control systems is driven by advances in electronics, computing, and materials science. These have enabled more sophisticated control algorithms, higher precision sensors, and more powerful microprocessors contributing to enhanced motor performance and efficiency.

Integration technology means putting more than one control system in one common hardware platform. Resource sharing and thereby optimum utilization is possible. The integrated systems can undertake several control jobs simultaneously and bring efficiency into the system as a whole, reducing the requirement for individual control units.

In turn, modular technology splits up the control system into independently responsible modules for specific functions and tasks of control. It improves maintainability and expandability by upgrading or replacing a single module without affecting the operation of the entire system. It allows the expansion of more flexible control solutions that can be developed for particular applications.

In the future, motor control systems will be more integrated and modularized. Greater efficiency and flexibility are the demands that call for these trends. Development in artificial intelligence and machine learning will also allow more adaptive and intelligent control strategies. The spread of IoT technology will also enable real-time monitoring and control over networks for more responsive and interconnected motor control systems.

Precise regulation of motor speed and torque is very important for enhancing industrial production efficiency and improving product quality.

This can be realized by applying sophisticated control algorithms with advanced technical apparatuses that can provide optimal controls. Due to endless technological advancement and ever-increasing application demands, motor control technology will continue in progressive development and refinement. It would mean greater support for the instrumental sectors such as industrial automation and intelligent manufacturing; therefore, these are moving at a faster pace. The above factors, when understood, will help in buying the right motor, while choosing the right brand is also important.

ENNENG specializes in the research and development of various types of permanent magnet motors. Our motors are designed to accurately control the speed and torque, making them ideal for a wide range of applications.

Reliability and flexibility in operation are some of the advantages that ENNENG motors boast. Our motors are designed to ensure consistent performance, safety, and reliability, hence guaranteeing smooth operation and efficiency in different industries.

Moreover, all the ENNENG motors are designed for low-speed with high-torque applications. Therefore, this would be most suitable for industries such as gold mines, coal mines, tire factories, oil wells, and water treatment plants, among others. The full touch control allows operating at the entire speed range with precision for customized operations.

Besides performance, energy-saving and environmental protection also contribute to the advantage of ENNENG motors. For example, replacing the traditional motor with our permanent magnet motor can save energy for customers in the tire industry by 7% to 40%. That will not only save operating costs but also help in sustainability.

From the option of power to cooling and intelligent monitoring, the motors at ENNENG offer an entire solution for industrial purposes. Our motors are known for durability, efficiency, and maintenance-free performance, thus becoming reliable for customers seeking high-quality motor solutions.

In a nutshell, ENNENG motors provide precision in speed and torque control, operational reliability, energy economy, and environmental protection. We will stick to the development of creative motor solutions for many industries continuously with our research and development commitment.