In the operational phase of an asynchronous motor, rotor winding requires the absorption of a portion of electrical energy originating from the grid for its excitation process. Consequently, this process utilizes and depletes grid energy. The absorbed electrical power is principally utilized by the current within the rotor’s winding mechanism to produce heat. This incurs loss accounting for approximately 20 to 30% of the motor’s total losses thereby reducing its overall efficiency.

Further into this system, after passing through stator windings, rotor excitatory currents transform into inductive currents. This transmutation initiates a lag between current entering stator windings and original grid voltage by specific angular measurements which subsequently diminishes motor’s power factor magnitude.

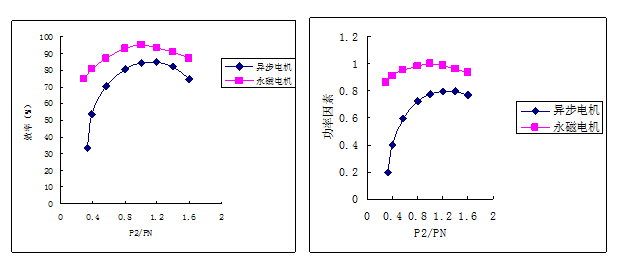

In addition, from the efficiency and power factor curves of the permanent magnet synchronous motor and asynchronous motor (Figure 1), it can be seen that when the load rate (=P2/Pn) of the asynchronous motor is less than 50%, its operating efficiency and operating power factor are greatly reduced, so it is generally required to operate in the economic zone, that is, the load rate is between 75% and 100%.

After the permanent magnet synchronous motor is embedded with a permanent magnet on the rotor, the permanent magnet is used to establish the rotor magnetic field. During normal operation, the rotor and the stator magnetic field run synchronously. There is no induced current in the rotor, and there is no rotor resistance loss. Only this one can improve the motor efficiency by 4%~50%.

Since there is no induced current excitation in the rotor of the permanent magnet motor, the stator winding may be a purely resistive load, making the motor power factor infinitely close to 1. From the efficiency and power factor curves of the permanent magnet synchronous motor and the asynchronous motor (Figure 1), it can be seen that when the load rate of the permanent magnet synchronous motor is > 20%, the operating efficiency and operating power factor of the permanent magnet synchronous motor do not change much, and the operating efficiency is >80%.

Figure 1 Efficiency and Power Factor vs. Load Rate Curves

Enneng’s TYB Series Standard Type Permanent Magnet Motor is known for its small size, high power factor, high efficiency&energy saving. There are various efficient permanent magnet motors produced by Enneng, please feel free to contact us.

When the asynchronous motor is working, there is current flowing in the rotor winding, and this current is completely consumed in the form of heat energy, so a lot of heat will be generated in the rotor winding, which will increase the temperature of the motor and affect the service life of the motor.

Due to the high efficiency of the permanent magnet motor, there is no resistance loss in the rotor winding, and there is less or almost no reactive current in the stator winding, so the temperature rise of the motor is low, and the extremely low-temperature rise also ensures the life of the permanent magnet and prolongs the service life of the motor. The comprehensive application of elevator traction machines also proves this point.

Due to the low power factor of the asynchronous motor, the motor must absorb a large amount of reactive current from the power grid, resulting in a large amount of reactive current in the power grid, power transmission and transformation equipment, and power generation equipment, which in turn reduces the quality factor of the power grid and increases the power grid and transmission. The load of substation equipment power generation equipment, and the reactive current consume part of the electric energy in the power grid, power transmission and transformation equipment, and power generation equipment, resulting in lower power grid efficiency and affecting the effective use of electric energy. Also due to the low efficiency of the asynchronous motor, to meet the requirements of output power, it is necessary to absorb more power from the grid, which further increases the loss of grid energy and aggravates the grid load.

There is no induced current excitation in the rotor of the permanent magnet motor, the power factor of the motor is high, the quality factor of the power grid is improved, and the compensator is no longer required to be installed in the power grid. At the same time, due to the high efficiency of the permanent magnet motor, electricity is also saved.

When the efficiency of a motor under rated load is increased from η1 to η2, the electric energy ws (kW·h) saved by the motor for one year of operation is as follows:

In the formula: PN—- rated power of the motor (kW);

LF%–motor operating load rate;

Th —- annual operating time (h).

Taking the rated working condition of the 22kW-4P motor as an example, the efficiency of the Y series asynchronous motor is 91.5%. When the efficiency is increased to 94.7% after changing to a high-efficiency permanent magnet motor, one unit can save electricity every year: 4.09×103 kW.h

Note: The above calculation is performed under the rated operating conditions. If the load rate changes and the operating conditions with a wide rotational speed range, the energy-saving effect is far greater than the rated point.

In comparison to asynchronous motors, permanent magnet synchronous motors present distinct benefits. These entail superior efficiency and power factor, optimal performance indicators, compact structure, lightweight nature, and minimal temperature rise. Moreover, they offer substantial energy savings along with enhancing the quality factor of power grids. They fully harness the capacity of existing power systems while also reducing investment in grid infrastructure. Most notably, they efficiently address the common issue of high-power motors driving light loads prevalent within electrical equipment operation.