With the continuous progress of science and technology, permanent magnet direct drive motors, as a type of high-efficiency, energy-saving, and environmentally friendly motor, have been widely used in ship propulsion systems. With high efficiency and low energy consumption, permanent magnet direct drive motors can significantly reduce the operating cost of ship propulsion systems, and at the same time, they are also conducive to improving the range and sailing speed of ships. However, in practical applications, permanent magnet direct-drive motors also face some challenges and problems.

Application of permanent magnet direct drive motor in ship propulsion system

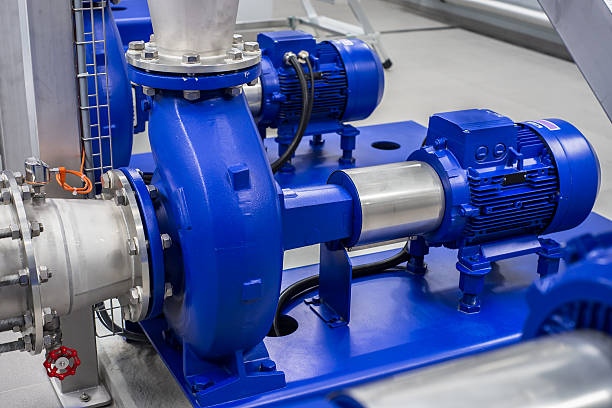

A ship’s systems that move it — like the main system, the sideways one, and the steering setup — use a magnet motor that doesn’t need gears. This magnet motor can step in for the old gear system in the main setup making the push system drive forward. It’s less about stuff wearing out and more about being reliable and lasting longer. Plus, it saves cash on fixing things and cuts back on how loud it is. When you look at the sideways system, the magnet motor allows the ship to move to the side and spin right where it is, which means it can handle better and do its job smoother. Also, this cool motor fits into the steering setup making the rudder quick to react and super precise in control. , without the provided original text, I cannot generate a paraphrased version. Please provide the text you would like to be paraphrased.

Advantages of a permanent magnet direct drive motor

Putting a permanent magnet direct drive motor to work on powering a boat has some cool benefits:

High efficiency and energy saving:The way these motors work, they’re super good at using energy, which means the boat’s power-hungry system doesn’t need as much juice leading to fewer bucks spent on fuel and overall expenses. If you put it side by side with old-school motors that are always running, these shiny new magnet motors are over 30% better at not wasting energy. That equals more money in your pocket and not as much bad stuff for the planet.

Simple structure and high reliability: Motors that use permanent magnets for direct drive pack a straightforward punch free from the usual wear and tear that bog down typical gear setups. Such durability translates to top-notch reliability for ship engines guaranteeing consistent performance at sea. It’s a big win since it cuts down on repair jobs and the need to swap out parts, trimming maintenance expenses.

Fast response speed: These motors can hustle picking up speed or hitting the brakes in a snap, which is awesome for boosting a vessel’s agility and how it handles overall. Thanks to this, ships are way better equipped to handle various types of sailing scenarios and switch between operational styles ramping up both navigational safety and comfort.

Low noise: Permanent magnet direct drive motors run with less noise than traditional gear drives. They make life better for the crew by creating a calmer work environment and offer passengers a more comfortable ride while cutting down on noise pollution.

Energy saving and emission reduction: These motors are super efficient using less power and helping to cut down on fuel needs and the release of greenhouse gases. This move is important for keeping our environment clean and pushing forward with sustainable growth. Companies using permanent magnet direct drive motors are doing their part for the planet.

Challenges of permanent magnet direct drive motors in ship propulsion system

Sure permanent magnet direct drive motors bring a bunch of pluses to the table, but when it comes to using them in marine propulsion, it’s not all smooth sailing.

Big swings in power use: When ships change how much power they use a lot, “permanent magnet direct drive” motors might not work as . So, it’s super important to have good control plans and safety steps in place. This way, we can keep the motors running right and make sure they last a long time.

Getting rid of extra heat: In the part of the ship that makes it move, we’ve got to tackle the issue of motors getting too hot. We can use neat designs and materials that handle heat well so the motor doesn’t get all overheated in super warm spots. Oh, and don’t forget to check the motors often, so if they start to overheat, you can fix it quick!

Space Cramped for Hooking It Up: When you’ve gotta shove that permanent magnet direct drive motor into a ship’s get-up-and-go system, there’s not a ton of room. So, ya gotta get smart about putting it together and figuring out how big and heavy it can be. If you nail down the motor’s bulk and poundage just right, it fits into tight spots way better and doesn’t cost you an arm and a leg to make or keep it running.

Wrap-Up

Let’s break it down: putting permanent magnet direct-drive motors to work in ship engines is getting popular. Why? They pack a punch with high efficiency superb energy saving, and they’re friends with the environment promising a bright future in maritime circles. But, hold up, it’s not all smooth sailing—there’s a bunch of hurdles to clear first. To push the envelope with these powerhouse motors, we’ve gotta amp up the research and the brainy stuff, get the crew savvier, nail down a solid upkeep routine, shout about it from the rooftops, and lean on the bigwigs for some policy backup. Plus, we need to buddy up to fuel progress and spread the know-how for these PMD motors making waves in sea travel.