Synchronous motors represent the ultimate in precision, efficiency, and adaptability within the realm of electromechanical equipment. Because of their operation in synchronism, such motors have become indispensable in many industries due to their stable speed control. This makes them irreplaceable when reliability and performance are the main concerns. In this comprehensive guide, we go on an enlightening journey into the multifaceted world of synchronous motors, delving into their diverse variations and intrinsic properties. Whether you are an industry professional looking to deepen your expertise or an enthusiast eager to understand the intricacies of motor technology, this article will hopefully provide you with a comprehensive insight into the world of synchronous motors.

Synchronous motors are the embodiment of variety. Each of the variations is tailored to different operating requirements. From the staid synchronous reluctance motors to the complicated permanent magnet synchronous motors, the range of available options underlines the adaptability of these machines in a host of applications. By understanding the specific characteristics and operating peculiarities of each type of motor, we will try to provide you with a subtle view of its capabilities, which would help you judge the best option to suit your specific industrial or commercial application.

With unparalleled precision in speed regulation, high torque output, and ease of integration with VFDs, synchronous motors are at the very edge of innovation-driving developments that range from renewable energy to aerospace engineering.

What is a synchronous motor?

Electric motors represent an electromechanical device in which electrical energy is transformed into mechanical energy. According to the type of input, they are divided into single-phase and three-phase motors. The most general three-phase motor types are synchronous motors and induction motors. In a case when three-phase electrical conductors are placed in specific geometric positions, i.e., at some angle from each other, an electric field is created. Rotation of the rotating magnetic field is performed with some speed that is called synchronous speed.

If an electromagnet is in this rotating magnetic field, the electromagnet is magnetically locked with the rotating field and rotates at the same speed as the rotating field. Hence, we call this kind of motor a synchronous motor because of the same speed of the motor rotor as the rotating magnetic field.

The most valuable characteristic of a synchronous motor is that it runs at a constant speed under all conditions of load, so long as the latter does not exceed the full capacity of the motor. This characteristic of running at constant speed is explained by the fact that the rotor is magnetically locked with the rotating magnetic field of the stator.

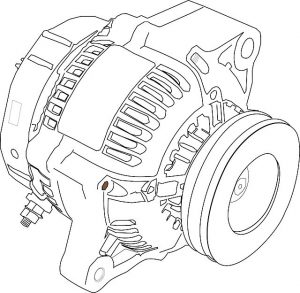

The overall structure of synchronous motor

In synchronous motors use a salient pole rotor. The term “salient pole” means that the magnetic poles of the rotor project towards the armature windings. The rotor of a synchronous motor is made up of laminated steel sheets. But why do the rotors use steel sheets? Laminations reduce the eddy current losses occurring in the transformer windings. Salient pole rotors are most used in the design of medium and low-speed motors. To provide high speed, motors are made with cylindrical rotors.

Types of synchronous motors

Now that we all are pretty familiar with synchronous motors, it’s better to get straight to the point. Synchronous motors, based on the method of magnetization of the rotor, can be classified into two types.

1) Non-excited synchronous motor

In this type, the rotor is of high-retention steel, like cobalt steel. The rotor at synchronous speed rotates with the rotating magnetic field of the stator. Hence, it has an almost constant magnetic field passing through it. Since the stator interacts with the rotor’s field, it becomes an electromagnet and has a north and south pole interacting with the stator’s field poles, so the rotor moves.

This type of synchronous motor has three categories and is available in three designs with unique features:

Hysteresis synchronous motor

Reluctance synchronous motor

Permanent magnet synchronous motor

1.A) Hysteresis synchronous motor

Hysteresis motors are single-phase motors. Their rotor comprises a ferromagnetic material. The rotor has high hysteresis loss characteristics. They are made of chromium, cobalt steel, or alnico. They are self-starting and require no additional windings. This means that once magnetized in a given direction, a wider hysteresis loop results; a large reverse magnetic field is required to reverse the magnetization.

1.B) Reluctance synchronous motor

The second design of unexcited synchronous motors is reluctance. A piece of iron that is rotating to complete the path of magnetic flux always provides minimum magnetic resistance. When the poles are in alignment with the magnetic field of the stator, the reluctance increases with the angle between the poles. This develops a torque that pulls the rotor into alignment with the poles near the magnetic field of the stator. The rotor poles are typical embedded squirrel-cage windings to provide torque below synchronous speed to start the motor.

1.C) Permanent magnet synchronous motor

Permanent magnet motors include permanent magnets inside a steel rotor to provide a constant magnetic flux. When the motor achieves synchronous speed, the rotor gets locked. The stator carries windings which are connected to an AC supply. A rotating magnetic field can be achieved. In construction and operational aspects, these motors are similar to brushless DC motors.

2) DC excitation synchronous motor

The stator windings and rotor windings are present. Synchronous DC-excited motors require DC excitation on the rotor to provide a magnetic field. The DC powering can either be through a separate DC source or a DC generator mounted on the motor shaft.

What are the uses of synchronous motors?

Synchronous motors find wide applications in industries and commercial uses due to some of their unique features and advantages. Their common uses are as follows:

-Power generation:

Synchronous generators in power plants are normally employed for generating electrical energy from mechanical energy. A synchronous motor works as a prime mover to the synchronous generator. Synchronous generators are very efficient and can handle precise voltage control with quite stable operation under various loads. Thus, these are considered ideal for power generation applications.

-Industrial manufacturing:

In these aspects, synchronous motors have a wide application in compressors, pumps, and fans of manufacturing equipment, which need exact speed control and high torque. Moreover, synchronous motors increase reliability and reduce maintenance frequency, making them a pretty attractive choice for industrial manufacturing.

What Are the Uses of Synchronous Motors?

Synchronous motors have extensive industrial, commercial, and consumer product applications. These particular features of synchronous motors have made them highly appealing in a wide variety of applications, from power generation to medical equipment, due to the requirement for precise speed control along with high efficiency and low maintenance. With further developments of motors, synchronous motors are going to play a significant role in meeting the requirements regarding energy and performance needs for various industries.

In a nutshell, synchronous motors are powerful machines that revolutionized the face of industries and commercial applications. As a result of their high precision, efficiency, and flexibility, synchronous motors have become indispensable in numerous industries. This guide is designed to give you a comprehensive understanding of the capabilities and benefits of synchronous motors by providing an overview of types of synchronous and their applications. As we forge ahead in the realms of technological innovation, synchronous motors will remain right at the forefront of this journey of transformation, driving progress across all industries.