·Grabbing Attention: Why Care About PMSMs?

·Material Quality of Permanent Magnets

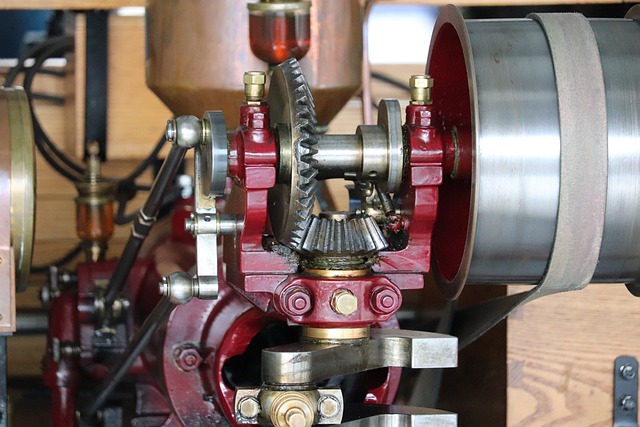

·Design and Construction of PMSMs

·Thermal Management in PMSMs

·Efficiency and Performance Metrics

·The Future of PMSMs: A Call to Action

In today’s rapidly evolving technological landscape, permanent magnet synchronous motors (PMSMs) play a pivotal role in driving innovation and sustainability across various industries. From powering electric cars to harnessing wind energy in turbines, the widespread application of PMSMs underscores their significance in shaping a greener and more efficient future.

PMSMs have become indispensable components in the systems of air compressor, contributing to the ongoing shift towards sustainable development. Moreover, these advanced motors are instrumental in the generation of renewable energy through wind turbines, enabling the efficient conversion of kinetic energy into electrical power. As such, their impact extends beyond individual machine to encompass large-scale renewable energy initiatives.

The versatility of PMSMs is evident in their deployment across diverse sectors, from automotive engineering to renewable energy production. Their ability to deliver high torque at low speeds makes them ideal for electric vehicle propulsion systems, while their exceptional efficiency ensures optimal power generation in wind turbines.

As the global demand for energy-efficient solutions continues to surge, ensuring the reliability and durability of PMSMs becomes paramount. By prioritizing these factors, businesses and industries can not only save substantial costs but also contribute significantly to environmental conservation efforts.

The utilization rate of permanent magnet synchronous motors is on an upward trajectory, with a notable increase in efficiency ratios reaching IE5 premium class standards. This enhanced efficiency translates into tangible cost savings for businesses while simultaneously reducing overall energy consumption. Furthermore, as PMSMs facilitate the transition towards green vehicles and sustainable energy production, they play a crucial role in mitigating environmental impact.

The market growth analysis indicates a robust expansion of the global PMSM market, with an anticipated value reaching $48.6 billion by 2027 at an impressive CAGR of 15.4%. This growth trajectory underscores the growing significance of PMSMs as key enablers of sustainable technological advancements.

Enneng’s PMSM is renown for its reliability and durability. If you are concerned about the quality of permanent magnet synchronous motor, Enneng low-speed high-power permanent magnet motor drive system should be your first choice. The following is parameters of Enneng low-speed high-power permanent magnet motor.

|

Torque range

|

7753000~100,000N·m

|

|

Seat No.

|

841315,355,400,500,560

|

|

Voltage

|

380VAC, 660VAC, 1140VAC, 3300VAC or 6K, 10K

|

|

Speed range

|

10~60, 75, 90rpm/min, or customized as per customers’ requirement40

|

|

Cooling type

|

natural cooling, water cooling

|

|

Installation

|

horizontal installed or customized as per customers’ requirement

|

|

Protection grade

|

IP54 (higher grades can be customized)

|

|

Shaft standard

|

circular shaft with keyway, hollow shaft with a key, hollow shaft with internal spline

|

As the heart of permanent magnet synchronous motors (PMSMs), the material quality of the magnets used is a critical factor in determining the overall performance and efficiency of these advanced motors.

The magnets utilized in PMSMs play a pivotal role in their functionality, with different types of magnets having varying impacts on motor performance. Permanent magnet synchronous motors commonly employ neodymium (NdFeB) or ferrite magnets, each offering distinct advantages and challenges. Neodymium magnets are known for their exceptional magnetic properties, providing high energy density and superior performance. On the other hand, ferrite magnets are valued for their cost-effectiveness and stability at elevated temperatures. The choice of magnet type directly influences the motor’s power output, efficiency, and operational temperature range.

In recent research on PMSM design and optimization, hybrid rare earth and ferrite materials have emerged as a promising avenue for enhancing motor performance while reducing reliance on scarce rare earth materials. This innovative approach presents two distinctive rotor topologies: series and parallel magnetic circuits, demonstrating the feasibility of achieving comparable performance with reduced rare earth material usage.

One significant challenge associated with permanent magnet synchronous motors is the scarcity of rare earth materials such as neodymium. This scarcity poses potential supply chain risks and cost fluctuations that can impact motor production and pricing. To address this challenge, researchers have explored novel methodologies for designing synchronous machines with field winding to reduce reliance on rare earth materials without compromising performance.

In addition to material scarcity, ensuring optimal cooling methods for PMSMs remains a key consideration in maintaining durability and reliability. A comprehensive review of cooling methods in PMSMs emphasizes the importance of effectively managing rotor iron temperatures to mitigate safety risks while maximizing operational limits.

The utilization of hybrid rare earth and ferrite materials represents a strategic response to addressing the scarcity of neodymium while maintaining high motor performance standards. This approach aligns with global efforts to optimize resource utilization in sustainable technological advancements.

The integration of copper water heat pipes and phase change material (PCM) has shown promise in enhancing thermal management within PMSMs by effectively regulating operational temperatures while minimizing reliance on scarce resources.

The ongoing pursuit of innovative solutions underscores the commitment to overcoming material challenges associated with permanent magnet synchronous motors while advancing towards more sustainable practices.

As technology continues to advance, the design and construction of permanent magnet synchronous motors (PMSMs) have become pivotal in achieving optimal performance and longevity. Beyond the basics of motor design, advanced engineering techniques significantly influence the durability and efficiency of these sophisticated machines.

The evolution of permanent magnet motor technology has led to advanced design methodologies that prioritize not only performance but also longevity. A comparative analysis between a Hybrid-Type Permanent Magnet Motor (HTPMM) and traditional prototypes reveals compelling insights into the advancements in motor design. The HTPMM exhibits similar performance to the traditional prototype while reducing rare earth material usage and lowering manufacturing costs. This innovative approach underscores the industry’s commitment to sustainable practices without compromising on operational excellence.

In addition, when comparing a Permanent Magnet Synchronous Machine (PMSM) with potential vector control for electric vehicle application, analytical implementation and design considerations are paramount for achieving maximum efficiency at the lowest costs. These comparisons highlight the intricate balance between cutting-edge design principles and cost-effective solutions in driving sustainable technological advancements.

Precision engineering and quality control measures during construction are imperative for ensuring the reliability and durability of PMSMs. The meticulous construction process involves stringent adherence to design specifications, material selection, and assembly techniques that collectively contribute to the overall performance of these advanced motors.

Moreover, different types of motors by efficiency rating demonstrate a notable shift towards embracing PMSMs over typical induction motors due to their higher efficiency class. This transition underscores the significance of construction techniques that prioritize energy-efficient solutions while meeting evolving industry standards.

When comparing surface-mounted permanent magnet synchronous motors (SPMSMs) with interior permanent magnet synchronous motors (IPMSMs), it becomes evident that SPMSMs exceed IPMSMs in efficiency by 1.5%, albeit with a higher reliance on rare earth magnets. This comparison emphasizes the critical role of construction techniques in optimizing motor configurations for enhanced efficiency while strategically managing resource utilization.

Furthermore, rotor cooling methods for PMSMs have been extensively studied to improve operational limits and reduce magnet temperatures. The comprehensive exploration of various cooling methods underscores the industry’s commitment to advancing thermal management strategies that directly impact motor construction and long-term reliability.

Thermal management is a critical aspect of ensuring the optimal performance and longevity of permanent magnet synchronous motors (PMSMs). Effective cooling systems and temperature regulation mechanisms are essential for maintaining the reliability and efficiency of these advanced motors.

The role of cooling systems in PMSMs cannot be overstated. A comprehensive review conducted to capture current research interests in cooling methods in PMSM provides valuable insights into the diverse approaches employed to manage thermal conditions within these motors. The study, published in the journal “Energies” in 2021, categorizes cooling methods based on their heat transfer mechanisms and assigns them to specific components within the motor. This systematic approach highlights the significance of tailored cooling solutions that address the unique thermal requirements of different motor components.

In addition to traditional air-cooling methods, advancements in liquid-based cooling media have garnered attention for their potential to enhance thermal management in PMSMs. The integration of innovative cooling technologies reflects a concerted effort to optimize operational temperatures while mitigating safety risks associated with excessive heat generation.

The impact of temperature on PMSM performance is multifaceted, influencing not only immediate operational efficiency but also long-term durability. Finding the balance between managing temperature extremes and maximizing motor performance is crucial for realizing the full potential of these advanced motors.

Research findings from the aforementioned study shed light on the correlation between temperature regulation and motor performance. By effectively controlling operational temperatures, businesses can mitigate thermal stress on motor components, thereby extending their lifespan and ensuring consistent performance over time.

Moreover, information on potential combinations of cooling methods for different motor components underscores the versatility and adaptability of thermal management strategies in addressing specific heat dissipation needs within PMSMs. This nuanced approach aligns with industry efforts to tailor thermal solutions that optimize motor performance across diverse operating conditions.

When it comes to evaluating the efficiency and performance of motors, including permanent magnet synchronous motors (PMSMs), specific key performance indicators (KPIs) play a crucial role in providing valuable insights. These KPIs encompass various metrics that gauge the motor’s operational effectiveness, energy utilization, and overall output power.

One essential KPI for assessing motor efficiency is the power factor, which indicates the ratio of real power to apparent power. In the context of PMSMs, a high power factor signifies efficient power usage and optimal energy conversion, reflecting the motor’s ability to minimize reactive power and deliver useful work effectively.

Additionally, the total harmonic distortion (THD) serves as a critical metric for evaluating the quality of electrical waveforms produced by motors. Low THD levels in PMSMs indicate minimal distortion in voltage and current waveforms, signifying superior motor performance with reduced electromagnetic interference.

Furthermore, torque ripple stands as a significant KPI that measures variations in torque output during motor operation. For PMSMs, minimizing torque ripple is paramount in ensuring smooth and consistent rotational motion, thereby enhancing operational stability and overall system reliability.

In comparison to conventional motor types, permanent magnet synchronous motors (PMSMs) exhibit distinct advantages that position them as high-efficiency and high-performance motor drives across diverse applications. The rapid development of permanent magnet manufacturing technologies has propelled PMSMs to achieve significantly increased efficiency and output power compared to other motor types that may not have experienced similar advancements.

The utilization of field excitation from permanent magnets coupled with sinusoidal back Electromotive Force (EMF) waveforms distinguishes PMSMs from other motors, contributing to their exceptional operational capabilities. This unique feature enables PMSMs to deliver enhanced efficiency while maintaining optimal performance standards across varying load conditions.

Moreover, the widespread adoption of direct-drive-type high-speed PMSMs underscores their high power density and efficiency compared to other motor types. This adoption reflects the industry’s recognition of PMSMs’ superior capabilities in driving sustainable technological advancements across sectors ranging from automotive engineering to renewable energy production.

In essence, the amalgamation of advanced manufacturing technologies with inherent design advantages positions permanent magnet synchronous motors at the forefront of efficient and reliable motor solutions. Their unparalleled efficiency gains stemming from innovative design principles solidify their status as leading performers in today’s dynamic technological landscape.

By leveraging these distinctive features and performance metrics, businesses can harness the full potential of PMSMs to drive sustainable innovation while achieving unparalleled operational excellence.

The landscape of the Permanent Magnet Synchronous Motor (PMSM) market is poised for dynamic shifts, driven by a relentless pursuit of innovation and technological advancement. Insights from industry analysts and experts underscore the pivotal role of embracing innovation as a catalyst for propelling the future of PMSMs towards unprecedented growth and sustainability.

The Road Ahead for PMSMs

As businesses navigate through an era characterized by rapid technological advancements, it becomes increasingly evident that the road ahead for PMSMs is paved with opportunities for transformative change. Recent innovations in PM manufacturing technologies have not only revolutionized efficiency and output power but have also positioned PMSMs as frontrunners in driving sustainable technological advancements across various industries.

The transition towards embracing Permanent Magnet Synchronous Motors represents a pivotal step towards realizing a greener and more sustainable future. Today’s industrial progress emphasizes optimizing energy consumption, with electrical motors playing a central role in this endeavor. With about 66% of electricity consumed by electrical motors, making the switch to high-efficiency motors such as PMSMs holds immense potential in driving substantial energy savings and environmental conservation efforts.

A Step Towards a Greener Future

The future outlook of the Permanent Magnet Synchronous Motor (PMSM) market presents an array of opportunities for businesses to align with sustainable practices while achieving operational excellence. Players, stakeholders, and other participants in this burgeoning market stand to gain invaluable insights from comprehensive research reports that offer an in-depth analysis of current trends and future scenarios within the industry. This strategic utilization positions them at an advantageous vantage point to drive meaningful change while contributing to global sustainability initiatives.

In conclusion, embracing innovation within the realm of Permanent Magnet Synchronous Motors presents unparalleled prospects for fostering sustainable technological advancements while making significant strides towards environmental conservation. Making informed decisions based on insightful research findings equips businesses with strategic leverage to shape a greener future powered by high-efficiency motor solutions like PMSMs.