The motor is an indispensable power device in modern industry and everyday life. The stability and reliability of its performance significantly influence the normal operation of various types of equipment and systems. Among the factors which determine the performance of motors, temperature is one of the most critical parameters. Temperature variations affect the efficiency, life, and reliability of motors and may even cause some safety problems. Therefore, it is of great importance to make clear the influence of temperature on motor performance and how to control the motor temperature.

The source of motor temperature

The main two parts that the temperature of the motor comes from are: one is the operation of the motor, due to the resistance heat generated by current in the conductor; another part, because of the friction of the internal parts in the motor and the load external applied to the motor mechanical energy, is converted to heat. These heats, if not released well on time, will cause an increase in the temperature of the motor.

The impact of temperature on motor performance

Efficiency decline: the higher the temperature, the more the efficiency of the motor will decline. The reason is that with the rise in temperature the copper loss and iron loss of the motor will rise thus reducing the power output of the motor.

Decrease in output torque: High temperatures are also responsible for reducing the output torque of the motor. In high temperatures, the resistance and magnetism of the windings and magnets of the motor change, respectively, thereby a slight difference in torque output.

Reduced insulation life: High temperatures make the insulation inside the motor deteriorate; hence, it reduces the life of the motor. If too high, it may result in further thermal decomposition and thermal breakdown of the insulating materials.

Increased vibration and noise: Due to the high temperatures, there is thermal expansion and thermal deformation inside the motor, which can result in increased vibration and noise, hence affecting normal operation.

Thermal Expansion and Thermal Deformation:High temperature causes thermal expansion and thermal deformation of internal parts of the motor to cause mechanical stress, therefore unstable operation or early wear of the motor.

Lubricant performance decline: The high temperature will lower the viscosity of the lubricant, affecting its lubrication effect. Hence, internal friction and wear increase.

The motor temperature control methods

Reasonable design of motor structure: Through the optimized structural design of the motor, heat generation and accumulation can be reduced. For instance, reasonable wiring and coil design can reduce copper loss and iron loss. Besides, reasonable ventilation design and heat dissipation structure design are also essential measures to reduce the temperature.

Selection of suitable insulating materials: When better heat-resistant and long-life insulating materials are selected, it can improve the motor in terms of heat resistance and extend the service life. Besides, the appropriate thickness of insulation materials also contributes to slowing down aging.

Installation of heat sinks: Cooling systems can be installed on the outer side of the motor shell, hence dissipating the heat generated by the generator. Large motors use either water cooling or oil cooling to dissipate heat.

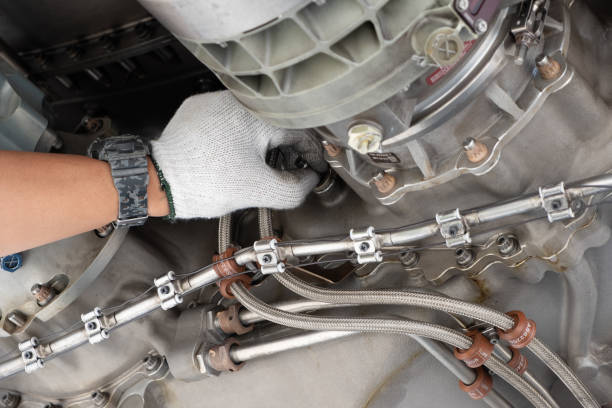

Regular maintenance and cleaning: Check the motor operating condition regularly, clean up the dust and debris inside the motor in time, which can improve the heat dissipation effect and reduce the accumulation of heat. Meanwhile, check the condition of lubricating oil to ensure its quality and quantity meet the requirements.

Use thermal protector:Putting a thermal protector on the motor will automatically cut off the power supply at high temperature and protect the motor against high temperature.

Optimize the operating environment: Keeping the operating environment of the motor clean and well-ventilated can reduce the effects that ambient temperature has on it. Also, adjustment to the load and the number of revolutions given to a motor will be able to cut down the amount of heating.

Adopt advanced temperature measurement technology: install temperature sensors and use advanced temperature measurement technology to monitor the real-time temperature change of the motor, so as to find abnormal conditions and deal with them in time.

Adoption of advanced cooling technology: using liquid cooling technology, heat pipe technology, and other advanced cooling technologies effectively reduces the operating temperature of the motor and improves stability and reliability.

Temperature monitoring and alarm system: It will be able to send out the alarm in time by establishing a perfect temperature monitoring and alarm system when there is an abnormal temperature, so that operators can take timely measures to deal with abnormalities.

In a word, temperature has so many influences on motors that the ways to control the temperature of motors also need to be put forward from multiple aspects. Through rational design, choosing appropriate materials, installation of heat-dissipation devices, regular maintenance, and cleaning, using thermal protectors, and other comprehensive application measures, it can effectively reduce the impact of temperature on motor performance and improve the stability and reliability of the motor.

Conclusion

The influence of temperature on motor performance cannot be ignored; controlling the temperature of the motor is the key to ensuring stable and reliable operation. Through reasonable selection of heat dissipation, optimization of design, the use of high thermal conductivity materials, intelligent control, and regular maintenance and other measures, the motor temperature can be effectively reduced, thereby improving the performance and life of the motor, while protecting equipment and personal safety. In the process of actual use, the appropriate control method should be chosen based on the situation, and timely adjustments and maintenance should be performed based on operating conditions. In the future, continuously developed technology will enable better and more intelligent motor temperature controls, which will offer greater technical support for wide application in all respects.