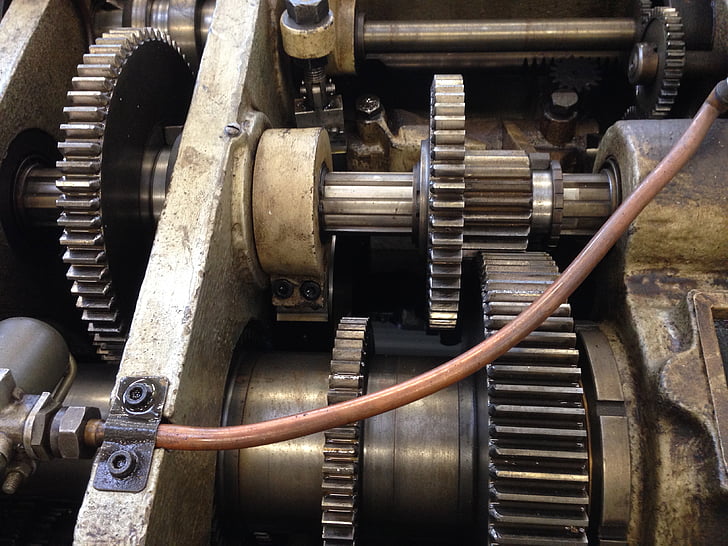

In traditional metal drawing equipment, there are problems of high energy consumption, complex structure and high maintenance cost. By adopting low-speed and high-torque permanent magnet direct-drive motor, we can effectively solve these problems. Promoting and applying this advanced motor technology will bring more efficient, energy-saving and environmentally friendly solutions to the wire drawing machine industry.

Advantages of permanent magnet direct drive motors

Permanent magnet direct drive motor adopts permanent magnet as the excitation source and realizes power transmission by directly driving the load. It has the following characteristics compared with the traditional frequency conversion speed control motor:

Low energy consumption: The simple structure of permanent magnet direct drive motor reduces the loss of mechanical transmission and improves the transmission efficiency. Compared with traditional motors, it can significantly reduce energy consumption and improve system efficiency.

High torque density: permanent magnet direct drive motors use high-performance permanent magnet materials with high magnetic field strength and magnetic energy density, which can provide greater output torque in a smaller volume.

Fast Response: Due to the direct drive of the load, permanent magnet direct drive motors are characterized by fast response, which enables precise control and regulation, and is suitable for applications with high speed and position requirements.

With these characteristics, the application of permanent magnet direct drive motors brings many advantages in the field of metal drawing machines:

High performance: The hydraulic or mechanical drives often used in traditional metal drawing machines suffer from high energy losses. The permanent magnet direct drive motor adopts the direct drive mode, which reduces the energy conversion link, improves the transmission efficiency, and thus reduces the energy consumption.

Energy saving and environmental protection: permanent magnet direct-drive motors are characterized by high efficiency and low energy consumption, which can reduce energy waste and is conducive to environmental protection. Compared with the traditional frequency conversion speed control motor, it can better meet the requirements of energy saving and emission reduction.

Low noise: traditional metal drawing equipment often produces noise pollution, which affects the working environment and workers’ health. The permanent magnet direct drive motor can provide a quieter working environment due to its direct drive method, which reduces the friction and vibration of the transmission parts.

Maintenance-free: Permanent magnet direct drive motors are characterized by simple structure and no additional maintenance work. Compared to traditional motors, it does not require regular lubricant replacement or repair of mechanical transmission parts, reducing maintenance costs and extending the service life of the equipment.

By adopting energy efficient permanent magnet direct drive motors, the metal drawing machine industry can realize more efficient, energy saving and environmentally friendly production methods. This advanced motor technology not only improves the transmission efficiency and service life of the equipment, but also reduces energy consumption and maintenance costs, bringing significant economic and environmental benefits to the organization.

Permanent magnet direct drive motors in wire drawing machines

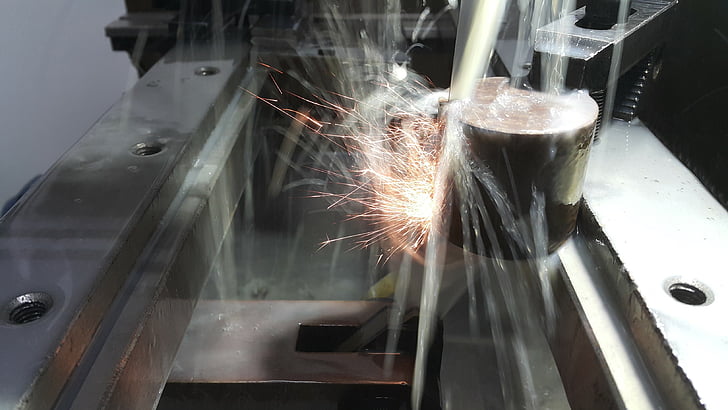

Permanent magnet direct drive motor is more and more widely used in the field of metal wire drawing machine. It plays an important role in wire drawing machine with its low speed and high torque. The process of metal wire drawing requires a large torque to stretch the metal material, the traditional frequency conversion speed control motor due to the existence of speed – torque characteristics of the limitations, often unable to meet this demand. Permanent magnet direct-drive motors have excellent low-speed high-torque performance and can provide stable and reliable output, ensuring the quality and efficiency of metal drawing.

Permanent magnet direct drive motors also excel in improving the inherent loss problems of traditional wire drawing machines. Traditional wire drawing equipment often uses hydraulic or mechanical transmission, due to the energy conversion links, transmission efficiency is low, there is a large amount of energy loss. The permanent magnet direct-drive motor adopts direct drive mode, which reduces the transmission link and lowers the energy conversion loss, thus improving the transmission efficiency and saving energy consumption.

In addition, due to the compact structure of the permanent magnet direct drive motor, no additional transmission device, can be more flexible layout in the wire drawing machine, saving valuable installation space. At the same time, permanent magnet direct-drive motors can provide more stable and reliable power output during the metal drawing process, which improves the efficiency of the motors and the overall productivity.

Comparison of permanent magnet direct-drive motor performance with asynchronous frequency-regulated motors

In the field of metal drawing machines, traditional asynchronous frequency-regulated motors often require additional transmission devices to achieve the required low-speed, high-torque output, and these transmission devices will bring about energy conversion losses. In contrast, permanent magnet direct drive motors use direct drive, reducing the energy conversion link and lowering the energy loss.

The power, power factor and energy saving target of permanent magnet direct drive motors change under different load conditions. According to the experimental data, compared with the traditional asynchronous frequency-regulated motor, the power of the permanent magnet direct drive motor is reduced by 15%, power factor by 30% and energy consumption target by 40% at 60% load. This shows that in the actual working process, permanent magnet direct drive motors can utilize energy more efficiently and reduce the waste of energy.

Conclusion

As a kind of energy-efficient drive technology, permanent magnet direct-drive motor has an important position and broad application prospects in the industrial field. In the future, the efficient drive will gradually replace the traditional drive technology. Permanent magnet direct-drive technology can not only play an important role in high-power equipment such as metal drawing machines, but also be applied to machinery manufacturing and other fields. Permanent magnet direct-drive motors are expected to be further developed to improve their own performance and be widely used in various industries, making a greater contribution to the promotion of sustainable development.